Canon MP830 Service Manual - Page 22

Repair, 3-1. Notes on Service Part Replacement

|

UPC - 013803052725

View all Canon MP830 manuals

Add to My Manuals

Save this manual to your list of manuals |

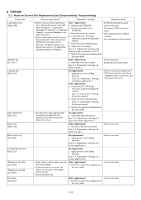

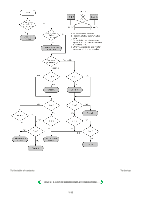

Page 22 highlights

3. REPAIR 3-1. Notes on Service Part Replacement (and Disassembling / Reassembling) Service part Notes on replacement*1 Adjustment / settings Operation check Logic board ass'y QM2-3659 - Before removal of the logic board After replacement: ass'y, remove the power cord, and 1. Initialize the EEPROM. allow for approx. 1 minute (for 2. Set the destination in the discharge of capacitor's accumulated EEPROM. charges), to prevent damages to the logic board ass'y. 3. Reset the waste ink counter. - Before replacement, check the waste ink amount (by service test print or EEPROM information print). [See 3-4. Verification Items, (1) 4. Correct the CD / DVD and automatic print head alignment sensors. 5. Check the ink system function. Service test print, or (2) EEPROM 6. Adjust the line feeding. information print, for details.] [See 3-3. Adjustment / Settings, (6) Service mode, for details of 1 to 6] - EEPROM information print - Service test print - Printing via USB connection - Copy - Direct printing from a digital camera - Fax transmission and reception 7. Perform the print head alignment in the user mode. Absorber kit QY5-0153 After replacement: 1. Reset the waste ink counter. [See 3.3. Adjustment / Settings, (6) Service mode.] - Service test print - EEPROM information print Carriage unit QM2-3025 At replacement: 1. Apply grease to the sliding portions. [See 3-3. Adjustment / Settings, (2) Grease application.] - Service test print (Confirm CD / DVD and automatic print head alignment sensor correction, and ink system function.) After replacement: 1. Correct the CD / DVD and automatic print head alignment sensors. [See 3.3. Adjustment / Settings, (6) Service mode.] 2. Check the ink system function. [See 3.3. Adjustment / Settings, (6) Service mode.] 3. Perform the print head alignment in the user mode. Paper feed motor QK1-1502 - The red screws securing the paper feed motor are allowed to be loosened. (DO NOT loosen any other red screws.) At replacement: 1. Adjust the paper feed motor. [See 3-3. Adjustment / Settings, (1) Paper feed motor adjustment.] Platen unit QM2-3565 After replacement: 1. Check the ink system function. [See 3.3. Adjustment / Settings, (6) Service mode.] - Service test print PR lift shaft ass'y QL2-0936 At replacement: 1. Apply grease to the sliding portions. [See 3.3. Adjustment / Settings, (2) Grease application.] - Service test print Carriage lift base unit QM2-2232 At replacement: 1. Apply grease to the sliding portions. [See 3.3. Adjustment / Settings, (2) Grease application.] Timing slit strip film QC1-6526 Timing slit disk film QC1-6229 - Upon contact with the film, wipe the After replacement: - Service test print film with ethanol. 1. Perform the print head alignment in - Confirm no grease is on the film. (Wipe off any grease thoroughly with ethanol.) the user mode. - Do not bend the film Print head QY6-0061 After replacement: - Service test print 1. Perform the print head alignment in the user mode. 1-17