Craftsman 28129 Operation Manual - Page 11

WARNING, To prevent personal

|

UPC - 009281290001

View all Craftsman 28129 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

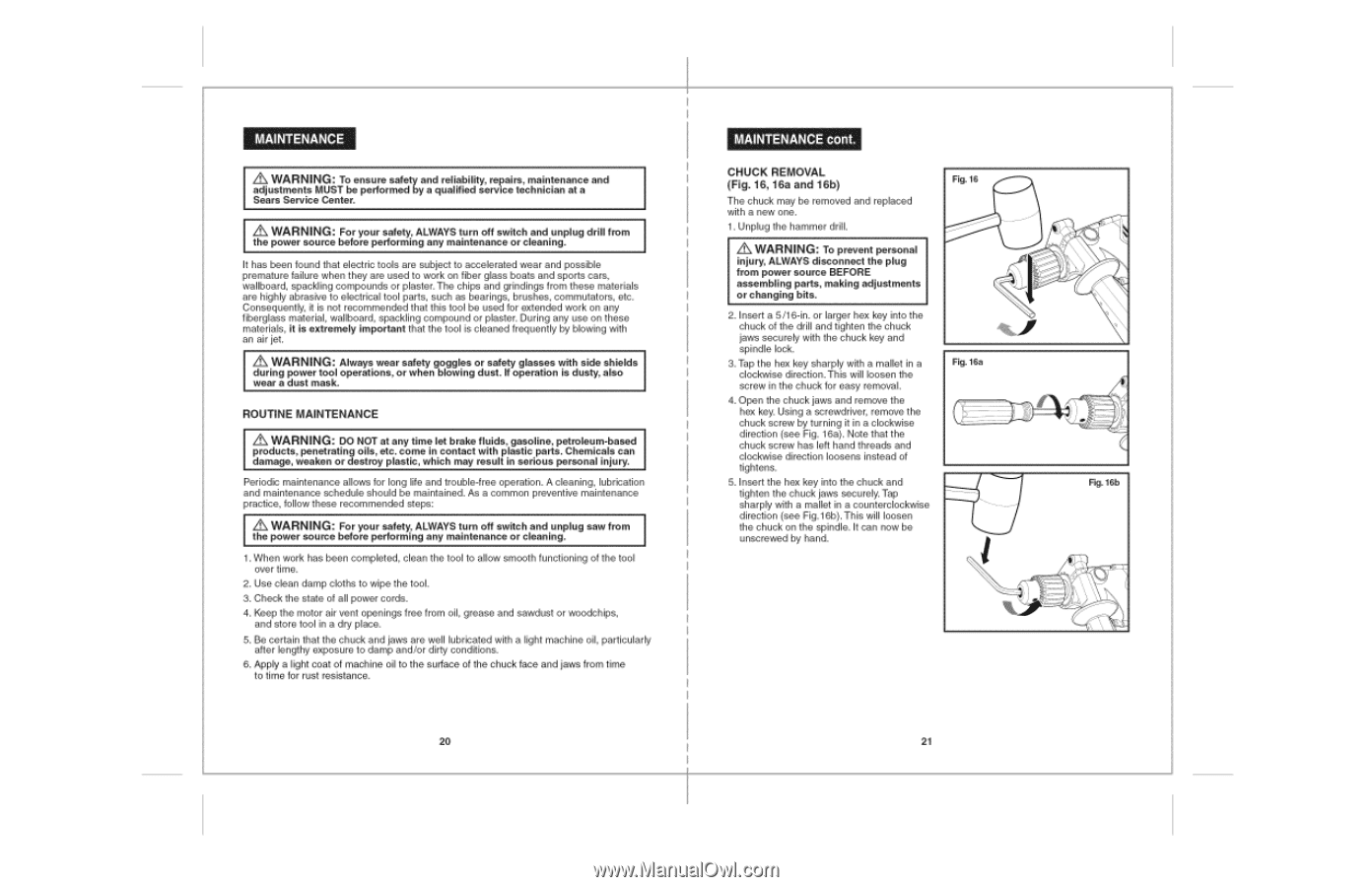

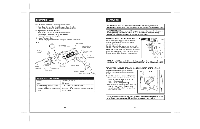

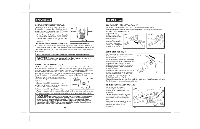

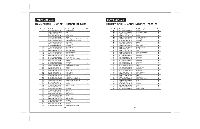

Z_ WARNING: To ensure safety and reliability, repairs, maintenance and adjustments MUST be performed by a qualified service technician at a Sears Service Center. WARNING: For your safety, ALWAYS turn off switch and unplug drill from the power source before performing any maintenance or cleaning. It has been found that electric tools are subject to accelerated wear and possible premature failure when they are used to work on fiber glass boats and sports cars, wallboard, spackling compounds or plaster. The chips and grindings from these materials are highly abrasive to electrical tool parts, such as bearings, brushes, commutators, etc. Consequently, it is not recommended that this tool be used for extended work on any fiberglass material, wallboard, spackling compound or plaster. During any use on these materials, it is extremely important that the tool is cleaned frequently by blowing with an air jet. z_ WARNING: Always wear safety goggles or safety glasses with side shields during power tool operations, or when blowing dust. If operation is dusty, also wear a dust mask. ROUTINE MAINTENANCE WARNING: DO NOT at any time let brake fluids, gasoline, petroleum=based products, penetrating oils, etc. come in contact with plastic parts. Chemicals can damage, weaken or destroy plastic, which may result in serious personal injury. Periodic maintenance allows for long life and trouble-free operation. A cleaning, lubrication and maintenance schedule should be maintained. As a common preventive maintenance )ractice, follow these recommended steps: _ WARNING: For your safety, ALWAYS turn off switch and unplug saw from the power source before performing any maintenance or cleaning. 1. When work has been completed, clean the tool to allow smooth functioning of the tool over time. 2. Use clean damp cloths to wipe the tool. 3. Check the state of all power cords. 4. Keep the motor air vent openings free from oil, grease and sawdust or woodchips, and store tool in a dry place. 5. Be certain that the chuck and jaws are well lubricated with a light machine oil, particularly after lengthy exposure to damp and/or dirty conditions. 6. Apply a light coat of machine oil to the surface of the chuck face and jaws from time to time for rust resistance. 20 CHUCK REMOVAL (Fig. 16, 16a and 16b) The chuck may be removed and replaced with a new one. 1. Unplug the hammer drill. WARNING: To prevent personal injury, ALWAYS disconnect the plug from power source BEFORE assembling parts, making adjustments or changing bits. 2. Insert a 5/16-in. or larger hex key into the chuck of the drill and tighten the chuck jaws securely with the chuck key and spindle lock. 3. Tap the hex key sharply with a mallet in a clockwise direction. This will loosen the screw in the chuck for easy removal. 4. Open the chuck jaws and remove the hex key. Using a screwdriver, remove the chuck screw by turning it in a clockwise direction (see Fig. 16a). Note that the chuck screw has left hand threads and clockwise direction loosens instead of tightens. 5. Insert the he)