Craftsman 28129 Operation Manual - Page 9

Spindle

|

UPC - 009281290001

View all Craftsman 28129 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

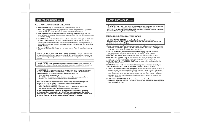

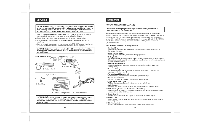

SPINDLELOCK (Fig. 10) The spindle lock is a convenience feature that allows you to tighten or loosen the chuck jaws around a bit without having to use the chuck key. 1. Unplug the hammer drill. 3 J i sZo_uWrceARBNEINFOGR: E aTsosepmrbelvinegnt ppearrstso,nmalakininjugrya,dAjuLsWtmAeYnSts disocroncnheacntgintghe bpitlsu.g from power | 2. Depress and hold the spindle lock button. 3. While keeping the button depressed, manually rotate the chuck until the spindle shaft "clicks" into a stationary position. Rotate clockwise for tightening, and counterclockwise for loosening. 4. Continue to rotate the chuck until the jaws are tight around the bit. If loosening, rotate until the jaws are free of the bit. 5. Release the spindle lock button. Fig. 10 _ \ Chuck Jaws Spindle Lock NOTE: To ensure that jaws are tight, you may want to insert the chuck key into the chuck and add an extra tightening twist. INSTALLING AND REMOVING ACCESSORY BITS (Fig. 11) You may install or remove bits using the spindle lock button as described above, or you may simply use the chuck key inserted into the chuck. If you use the chuck key, you don't have to depress the spindle lock button. To loosen or tighten chuck with chuck key: 1. Unplug the hammer drill i s_oWurAceRNBINEFGO:RE aTsosepmrbelvinegnt ppearrstso,nmalakininjugrya,dAjuLsWtmAeYnSts disocroncnheacntgintghe bpitlsu.g from power 2. Insert chuck key into one of the holes in the side of the chuck. Turn key to tighten or loosen jaws for installing or removing bit 3. If tightening, hold bit firmly in place. Always make sure bit is tightly secured in the chuck jaws before beginning operation. Fig. 11 Chuck Chuck Jaws 16 BUBBLE LEVEL (Fig. 12) In order to insure a perfect right angle when drilling / driving and hammer drilling into a workpiece, you can use the built-in bubble level on the back of the drill / driver. The bubble level is designed to work when the hammer drill is in a horizontal position. Line the air bubble up in the appropriate circle, and to the workpiece. This will help insure that you will drill / drive or hammer drill straight into the workpiece. Fig. 12 LIVE TOOL INDICATOR LIGHT (Fig. 13) Your hammer drill has a LIVE TOOL INDICATOR green LED light that comes on when the drill is plugged into a power source. This lets you know you have a live tool. Fig. 13 Green LED Light Level OPERATING THE HAMMER DRILL AS A DRILL / DRIVER When using your 1/2-in. Hammer Drill for standard drill/driving applications, make sure you have the Rotary and Hammer Drilling Selector Switch in the Rotary Drilling position (see Page 13, Fig. 4). NOTE: When unplugging the drill, first make sure that the Power Lock-On Feature is not engaged, by pressing on the trigger switch to release it. Failure to do so will cause the hammer drill to start immediately the next time it is plugged in. Property damage or serious personal injury could result. ROTARY DRILLING (Fig. 14) 1. Always unplug the drill when installing or removing bits and accessories. 2. Use sharp bits only. Always use Craftsman bits and accessories to help ensure desired performance. 3. For drilling in wood use twist drill bits, spade bits, power auger bits and hold saws. 4. Start drilling in wood with slow speed and increase to full power while applying firm pressure on the hammer drill. 5. Pull the bit out of the hole frequently to clear the wood chips away from the flutes to help keep the bit from overheating. 17