Cub Cadet PRO Z 160S EFI Owners Manual - Page 18

Service

|

View all Cub Cadet PRO Z 160S EFI manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

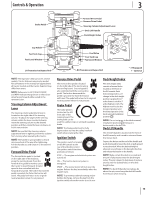

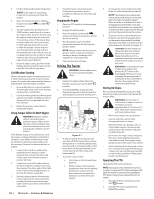

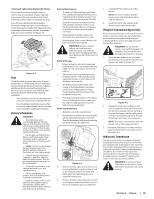

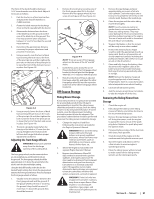

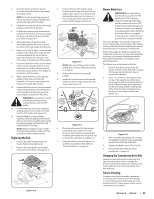

Service Maintenance Schedule Check Engine Intake Screen/Cover Clean Transmission Cooling Slots Clean Battery Terminals Clean Engine Cooling Fins Lube Deck Spindles Lube Deck Wheels Lube Front Wheel Bearings Lube Caster Pivots Lube Pivot Points & Linkage NOTE: This Operator's Manual covers several models. Tractor features may vary by model. Not all features in this manual are applicable to all tractor models and the tractor depicted may differ from yours. Maintenance WARNING! Before performing any maintenance or repairs, disengage the PTO, move the drive control levers fully outward in the neutral position engaging the parking brake, stop the engine and remove the key to prevent unintended starting. Lubrication • Using a pressure lubricating gun, lubricate the front caster wheel axles with Cub Cadet 251H EP grease after every 10 hours of service. • Periodically lubricate all other pivot points with a quality lubricating oil. Engine Refer to the Engine Operator's Manual for all engine maintenance intervals, procedures, specifications and instructions. Changing the Engine Oil WARNING ! If the engine has been recently run, the engine, muffler and surrounding metal surfaces will be hot and can cause burns to the skin. Exercise caution to avoid burns. Maintain oil level as instructed in Engine Operator's Manual. Be careful not to spill oil on any of the belts. 18 Before Each use P P Every 10 Hours P To complete an oil change, proceed as follows: 1. Run the engine for a short time to warm the engine oil. The oil will flow more freely and carry away more impurities. Use care to avoid burns from hot oil. 2. Locate the oil drain hose on the engine. See Figure 4-1. Figure 4-1 3. Remove the hose from the clip securing it to the frame. 4. Route the free end of the oil drain hose toward an appropriate oil collection container with at least a 2.5 quart capacity, to collect the used oil. NOTE: Avoid getting oil on the muffler when draining. 5. While holding the free end of the oil drain hose over the oil collection container, unscrew the square-head hose plug from the end of the hose. See Figure 4-1. Drain the engine oil into the collection container. 6. After draining the oil, wipe any residual oil from the oil drain hose. Thread the square head plug into the drain hose fitting and fully tighten the plug. Every 25 Hours 4 Prior to Storing P P P P P P P P P P P P 7. Refill the engine with new oil. Refer to the Engine Operator's Manual for information regarding the volume and weight of engine oil. 8. Place the hose back into the clip securing it to the frame. Lubrication WARNING! Before lubricating, repairing, or inspecting, always disengage PTO, set parking brake, stop engine and remove key to prevent unintended starting. Pivot Points & Linkage Lubricate all the pivot points on the drive system, parking brake and lift linkage at least once a season with light oil. Wheels & Caster Pivots Each of the front wheel axles, rims and caster pivots are equipped with grease fittings (a). Lubricate with a No. 2 multi-purpose grease applied with a grease gun after every 25 hours of tractor operation. (a) Figure 4-2