Dell 1320c User Guide - Page 39

Recommended Paper, Unacceptable Paper, Selecting Paper - software

|

UPC - 662919013061

View all Dell 1320c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 39 highlights

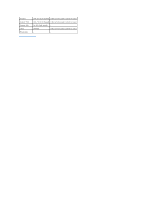

Most high-quality xerographic paper is made from 100% chemically pulped wood. Paper containing fibers such as cotton possess characteristics that can result in degraded paper handling. Recommended Paper To ensure the best print quality and feed reliability, use 75 g/m2 (20 lb) xerographic paper. Business papers designed for general business use also provide acceptable print quality. Only use paper able to withstand high temperatures without discoloring, bleeding, or releasing hazardous emissions. The laser printing process heats paper to high temperatures. Check with the manufacturer or vendor to determine whether the paper you have chosen is acceptable for laser printers. Always print several samples before buying large quantities of any type of print media. When choosing any print media, you should consider the weight, fiber content, and color. Unacceptable Paper The following paper types are not recommended for use with the printer: l Chemically treated papers used to make copies without carbon paper, also known as carbonless papers, carbonless copy paper (CCP), or no carbon required (NCR) paper l Preprinted papers with chemicals that may contaminate the printer l Preprinted papers that can be affected by the temperature in the printer fuser l Preprinted papers that require a registration (the precise print location on the page) greater than ±0.09 inches, such as optical character recognition (OCR) forms In some cases, you can adjust registration with your software program to successfully print on these forms. l Coated papers (erasable bond), synthetic papers, thermal papers l Rough-edged, rough or heavily textured surface papers, or curled papers l Recycled papers containing more than 25% post-consumer waste that do not meet DIN 19 309 l Multiple-part forms or documents l Print quality may deteriorate (blank spaces or blotches may appear in the text) when printing on talc or acid paper. Selecting Paper Proper paper selection helps prevent jams and ensures trouble-free printing. To help avoid jams or poor print quality: l Always use new, undamaged paper. l Before loading the paper, identify the recommended print side of the paper. This information is usually indicated on the paper package. l Do not use paper that you have cut or trimmed yourself. l Do not mix print media sizes, weights, or types in the same source. This may result in a paper jam. l Do not remove the tray while a job is printing. l Ensure that the paper is properly loaded in the tray. l Flex paper back and forth, and then fan them. Straighten the edges of the stack on a level surface.