Dell External OEMR XL R610 Technical Guide - Page 46

R610 Static Rails, Supported Racks

|

View all Dell External OEMR XL R610 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 46 highlights

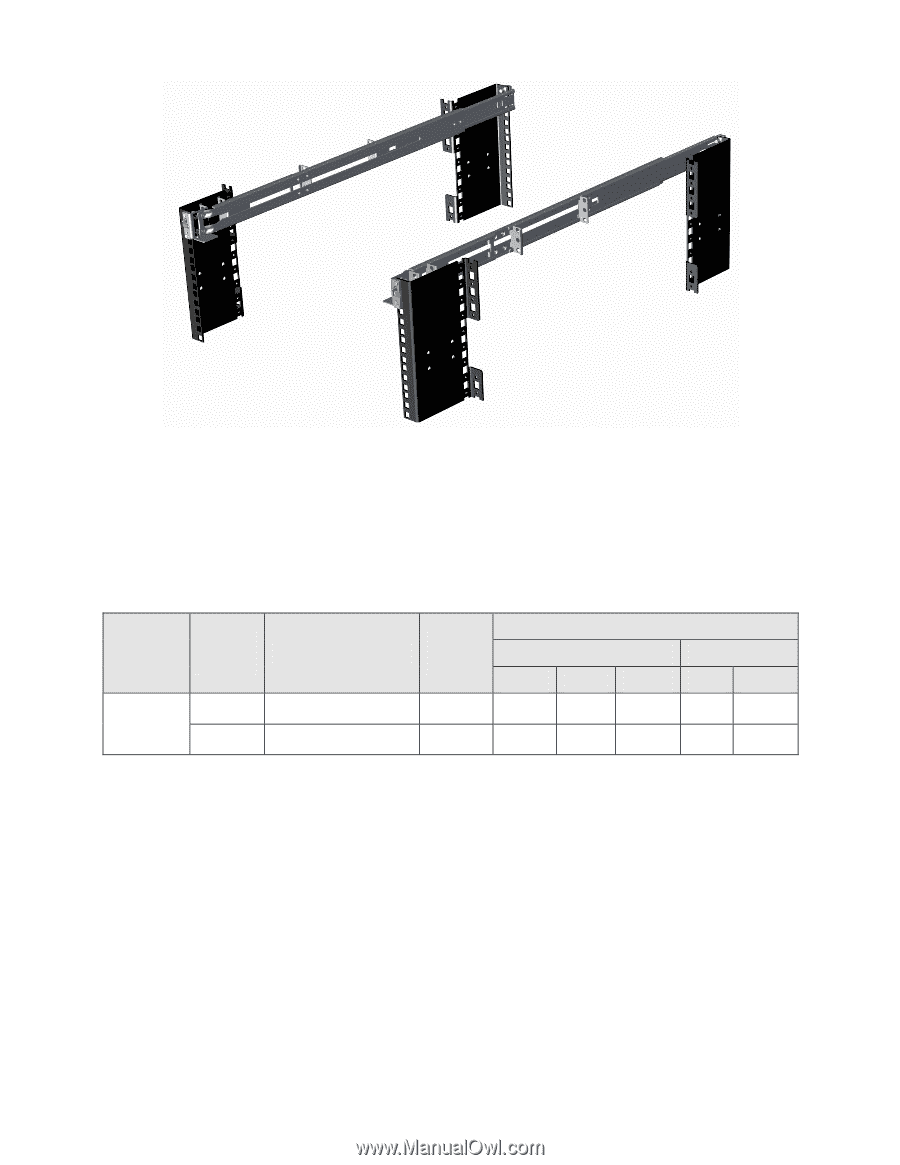

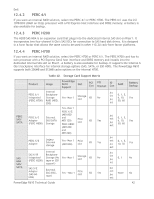

Dell Figure 10. R610 Static Rails One key factor in selecting the proper rails is identifying the type of rack in which they will be installed. Both the sliding rails and the static rails support toolless mounting in 19‖-wide, EIA-310-E compliant square hole and unthreaded round hole racks via the ReadyRails™ mounting interface, but only the static rails, as the more generic or universal solution, support mounting in threaded hole and 2-post (Telco) racks. Product Rail ID A1 R610 A2 Table 14. Supported Racks Mounting Interface Rail Type Rack Types Supported 4-Post 2-Post Square Round Thread Flush Center ReadyRails™ Sliding √ √ X X X ReadyRails™/Generic Static √ √ √ √ √ Screws are not included in the static rail kit because the threaded racks are offered with a variety of thread designations. Users must provide their own screws when mounting the static rails in threaded or 2-post racks. Other key factors governing proper rail selection include the spacing between the front and rear mounting flanges of the rack, the type and location of any equipment mounted in the back of the rack such as power distribution units (PDUs), and the overall depth of the rack. See Table 15. Due to their reduced complexity and lack of need for CMA support, the static rails offer a greater adjustability range and an overall smaller footprint than the sliding rails. PowerEdge R610 Technical Guide 46