HP Latex 2700 User Guide 2 - Page 10

Manual loading

|

View all HP Latex 2700 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

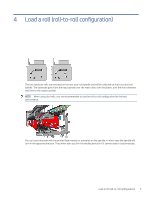

5. 5. Rest the ends of the spindle on the platforms provided at the rear of the printer; plastic pads are provided to absorb the impacts. 6. In the same way, load the spindle with the empty core into the front of the printer. In this case, the geared end of the spindle should be on the right. Manual loading The following steps provide the complete procedure for this topic. NOTE: Assisted loading is not recommended in a dual-roll configuration. 1. Use the Internal Print Server to raise the carriage beam to its loading position, or use the physical button. 2. Open the front door and the curing module. 3. Open the loading table. 4. Unlock the differential in the input spindle. 5. Unwind a length of substrate from the first input roll and place it in the print zone. 6. Push the substrate from the first roll through the printer until it reaches the output spindle. 7. Unwind a length of substrate from the second input roll and place it in the print zone. 8. Push the substrate from the second roll through the printer until it reaches the output spindle. 9. Align the substrate by checking that the substrate edge is in the same position on the input and output spindles. This can be done by using the rulers on the spindles or by measuring the distance between the right edge and the side plate. NOTE: You are recommended to align the edges of both rolls by the lines on both sides of the spindle's center mark. Manual loading 7