HP Latex 2700 User Guide 2 - Page 11

diameters, and it also checks the width of the roll, the winding direction, the vacuum

|

View all HP Latex 2700 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

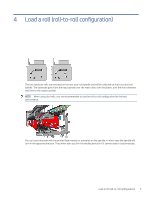

NOTE: The substrate-advance sensor must be covered by the substrate. 10. When the substrate is evenly tensioned and flat (no wrinkles or bumps, attach it to each empty core with adhesive tape. Tape it first in the center, and then at the left and right sides, making sure not to pull the substrate excessively or leave it wrinkled. 11. If you are using them, place the four substrate edge holders into position and attach them at the front. 12. Close the front door and the curing module. 13. If you are using them, attach the substrate edge holders. 14. Close the loading table. 15. Ensure that the spindle differentials are unlocked. 16. Use the Internal Print Server to lower the carriage beam to its printing position. 17. Go to the Internal Print Server and tap the Finish button. The printer rotates the rolls to check their diameters, and it also checks the width of the roll, the winding direction, the vacuum, and the substrateadvance calibration (this takes about a minute). NOTE: Some substrates (such as transparent substrates) cannot be measured by the printer in this way. In such cases, you will be asked to enter the Left Edge and Width fields yourself into the Internal Print Server. Use the ruler on the spindle to check these values. 8 Chapter 4 Load a roll (roll-to-roll configuration)