Husqvarna T525 Owner Manual - Page 26

To do a check of the spur sprocket, To lubricate the needle bearing, To examine the cutting

|

View all Husqvarna T525 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 26 highlights

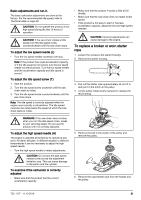

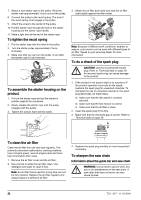

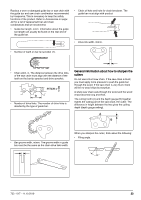

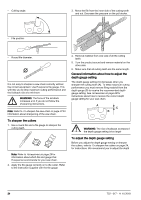

To do a check of the spur sprocket The clutch drum has a spur sprocket that is welded on the clutch drum. 3. Compare the saw chain with a new saw chain to examine if the rivets and links are worn. 4. Replace the saw chain when the longest part of the cutting tooth is less than 4 mm/0.16 in. Also replace the saw chain if there are cracks on the cutters. • Regularly do a visual check of the degree of wear on the spur sprocket. Replace the clutch drum with the spur sprocket if there is too much wear. To lubricate the needle bearing 1. Pull the front hand guard rearward to disengage the chain brake. 2. Loosen the bar nuts and remove the clutch cover. Note: Some models have only one bar nut. 3. Put the product on a stable surface with the clutch drum up. 4. Remove the clutch drum and lubricate the needle bearing with a grease gun. Use engine oil or a bearing grease of high quality. To do a check of the guide bar 1. Make sure that the oil channel is not blocked. Clean if it is necessary. 2. Examine if there are burrs on the edges of the guide bar. Remove the burrs using a file. 3. Clean the groove in the guide bar. To examine the cutting equipment 1. Make sure that there are no cracks in rivets and links and that no rivets are loose. Replace if it is necessary. 4. Examine the groove in the guide bar for wear. Replace the guide bar if it is necessary. 2. Make sure that the saw chain is easy to bend. Replace the saw chain if it is rigid. 26 732 - 017 - 11.10.2019