Husqvarna V548 - 2023 Owner Manual - Page 22

To install the deck belt, To do a check of the engine oil level, To install

|

View all Husqvarna V548 - 2023 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

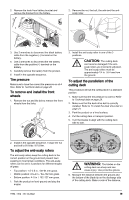

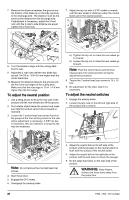

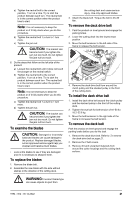

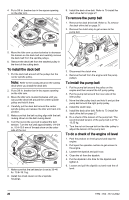

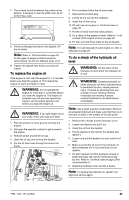

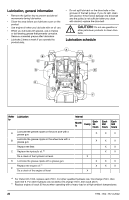

4. Put a 3/8 in. breaker bar in the square opening on the idler arm. 9. Install the deck drive belt. Refer to To install the deck drive belt on page 21. To remove the pump belt 1. Remove the deck drive belt. Refer to To remove the deck drive belt on page 21. 2. Remove the clutch stop to get access to the pump belt. 5. Move the idler arm counterclockwise to decrease the tension on the deck belt and carefully remove the deck belt from the spindle pulleys. 6. Remove the deck belt from the stacked pulley in the front of the cutting deck. To install the deck belt 1. Put the deck belt around all the pulleys but the center spindle pulley. Note: Refer to the routing decal on the cutting deck when you install the deck belt. 2. Put a 3/8 in. breaker bar in the square opening on the idler arm. 3. Move the idler arm counterclockwise until you can put the deck belt around the center spindle pulley and hold it there. 4. Carefully put the deck belt around the center spindle pulley and release the idler arm back into position. 5. Make sure that the belt routing align with the belt routing shown on the belt routing decal. 6. Turn the nut on the eye bolt to adjust the belt tension. Turn the nut until approximately 1/4-3/4 in. / 6.4-19.0 mm of threads show on the outer side of the nut. 7. Make sure that the belt tension is set to 30-40 lb / 13.6-18.1 kg. 8. Install the 2 belt covers on the 2 spindle housings. 3. Disconnect the clutch wire. 4. Remove the belt from the engine and the pump pulleys. To install the pump belt 1. Put the pump belt around the pulley on the engine and then around the left pump pulley. 2. Put the pump belt around the inner side of the idler pulley. 3. Move the idler pulley back and hold it and put the pump belt around the right pump pulley. 4. Install the clutch stop. 5. Install the deck drive belt. Refer to To install the deck drive belt on page 21. 6. Do a check of the tension of the pump belt. The recommended tension of the pump belt is 27 lb / 12.25 kg. 7. Turn the nut on the eye bolt on the idler pulley to adjust the tension of the pump belt. To do a check of the engine oil level 1. Park the product on level ground and stop the engine. 2. Pull open the operator cushion to get access to the engine. 3. Loosen the dipstick and pull it out. 4. Clean the oil from the dipstick. 5. Put the dipstick in the hole for the dipstick and tighten it. 6. Loosen and pull the dipstick out and read the oil level. 22 1994 - 002 - 05.12.2022