LG DLGX3701W Owners Manual - Page 18

Venting the Dryer, Ductwork

|

View all LG DLGX3701W manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

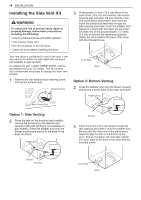

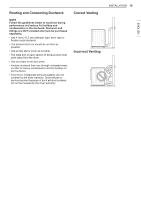

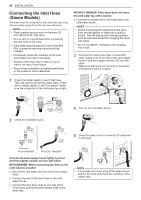

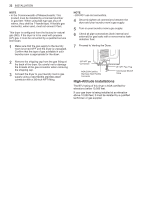

18 INSTALLATION Venting the Dryer WARNING To reduce the risk of fire or explosion, electric shock, property damage, injury to persons or death when using this appliance, follow basic safety precautions, including the following: • Do not crush or collapse ductwork. • Do not allow ductwork to rest on or contact sharp objects. • If connecting to existing ductwork, make sure it is suitable and clean before installing the dryer. • Venting must conform to local building codes. • Gas dryers MUST exhaust to the outdoors. • Use only 4-inch (10.2 cm) rigid, semi-rigid or flexible metal ductwork inside the dryer cabinet and for venting outside. • To reduce the risk of fire, combustion, or accumulation of combustible gases, DO NOT exhaust dryer air into an enclosed and unventilated area, such as an attic, wall, ceiling, crawl space, chimney, gas vent, or concealed space of a building. • To reduce the risk of fire, DO NOT exhaust the dryer with plastic or thin foil ducting. • The exhaust duct must be 4-inch (10.2 cm) in diameter with no obstructions. The exhaust duct should be kept as short as possible. Make sure to clean any old ducts before installing your new dryer. • Rigid, semi-rigid or flexible metal ducting is recommended for use between the dryer and the wall. All non-rigid metal transition duct must be UL-listed. Use of other materials for transition duct could affect drying time. • DO NOT use sheet metal screws or other fasteners which extend into the duct that could catch lint and reduce the efficiency of the exhaust system. Secure all joints with duct tape. • Do not exceed the recommended duct length limitations noted in the chart. Failure to follow these instructions may result in extended drying times, fire or death. WARNING • Ductwork is not provided with the dryer. You should obtain the necessary ductwork locally. The vent hood should have hinged dampers to prevent backdraft when the dryer is not in use. • The total length of flexible metal duct must not exceed 8 ft. (2.4 m). Ductwork Wall Cap Type Recommended a Number of 90° Elbows 0 1 2 3 Maximum length of 4-inch diameter rigid metal duct 65 ft.(19.8 m) 55 ft.(16.8 m) 47 ft.(14.3 m) 36 ft.(11.0 m) a 4 a: 4" (10.2 cm) Use only for short 0 run installations 1 2 b 3 b: 2.5" (6.35 cm) 4 28 ft.(8.5 m) 55 ft.(16.8 m) 47 ft.(14.3 m) 41 ft.(12.5 m) 30 ft.(9.1 m) 22 ft.(6.7 m) NOTE • Deduct 6 ft. (1.8 m) for each additional elbow. Do not use more than four 90° elbows. • In Canada, only those foil-type flexible ducts, if any, specifically identified for use with the appliance by the manufacturer should be used. In the United States, only those foil-type flexible ducts, if any, specifically identified for use with the appliance by the manufacturer and that comply with the Outline for Clothes Dryer Transition Duct, Subject 2158A, should be used.