LiftMaster GH GT- Logic 4 Installation Manual - Page 24

AUXILIARY REVERSAL SYSTEM / RPM SENSOR, Auxiliary Reversal System, Feature, Benefit, ADJUST TORQUE - clutch adjustment

|

View all LiftMaster GH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

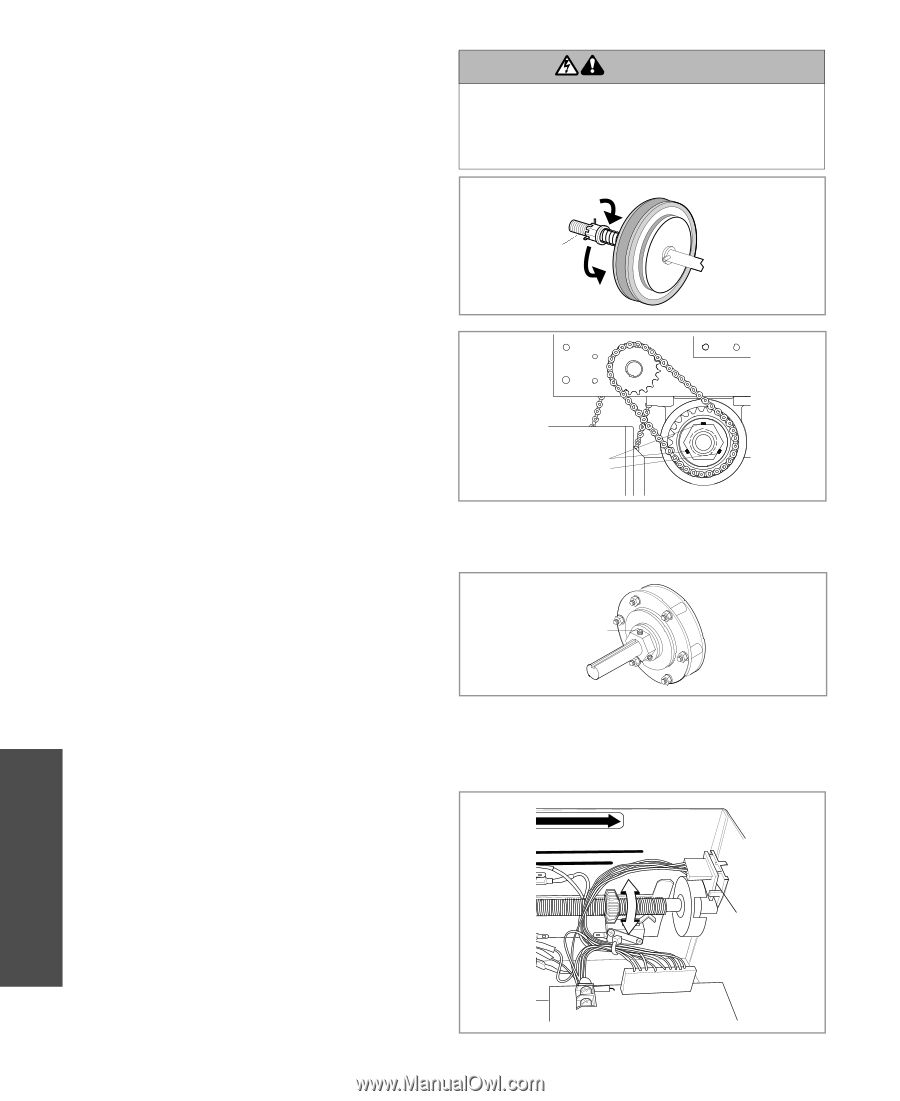

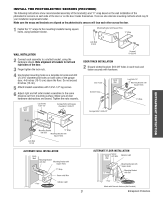

WARNING WARNING C(BLEULTCTCADHRUAIVDTEJIUOMSONTDMEELNOTPERATORS) 1 Remove the cotter pin from the clutch nut on the clutch shaft. 2 Turn the clutch nut to release tension. 3 Re-tighten the clutch nut until there is just enough tension to permit smooth operation of the door and to allow the clutch to slip if the door is obstructed. 4 Secure the clutch nut with the cotter pin. AVERTISSEMENT WARNING To avoid SERIOUS personal INJURY or DEATH from electrocution: • Disconnect electric power BEFORE performing ANY adjustments or maintenance. 12 4 AV3ERTISSEMENT ATTENTION ADJUST TORQUE LIMITER CLUTCH (MODEL GT) 1 Loosen set screws of torque adjustment nut on the gear reducer. 2 Back off torque nut until there is very little tension on the belleville washers. 3 Tighten torque nut gradually until there is just enough tension to permit the operator to move the door smoothly through a complete open/close cycle, but to allow the reducer to slip if the door is obstructed. 4 Re-tighten the set screw that is directly over the flat portion of the shaft. AVERTISSEMENT Torque Nut Set Screws MODEL GH (OPTIONAL MODIFICATION) 1 Loosen set screws on clutch nut. Back off clutch nut until there is very little tension on the 2 ADVERTENCIA clutch spring. 3 Tighten clutch nut gradually until there is just enough tension to permit the operator to move the door smoothly but to allow PRECAUCIÓN the clutch to slip if the door is obstructed. When the clutch is properly adjusted, it should generally be possible to stop the door by hand during travel. (3) Set Screws ADVERTENCIA ADVERTENCIA ADJUSTMENT AUXILIARY REVERSAL SYSTEM / RPM SENSOR The Auxiliary Reversal System is designed to protect the door and motorized operator. It is NOT a substitute for a safety sensing device. Feature: This feature utilizes the RPM sensor connected to the logic board to detect when the clutch slips and reverses the door (clutch must be properly adjusted). In addition, the RPM eliminates the need for a centrifugal switch on single phase motors. Benefit: The Auxiliary Reversal System reverses the operator upon hitting an obstruction, preventing excessive door and operator damage. We require the use of safety devices for primary safety protection. By removing the centrifugal switch on single phase motors, the leading cause of motor failures is eliminated. (Auxiliary Reversal System not applicable on models GH and GT.) NOTE: This feature is automatically learned and does not require programming. Adjustment - Clutch adjustment 24 LOSE OPEN RPM Sensor Logic Board