Ryobi A18MS01G Operation Manual - Page 6

Assembling And Installing Material, Work Supports, Attaching Saw Mounting Brackets

|

View all Ryobi A18MS01G manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

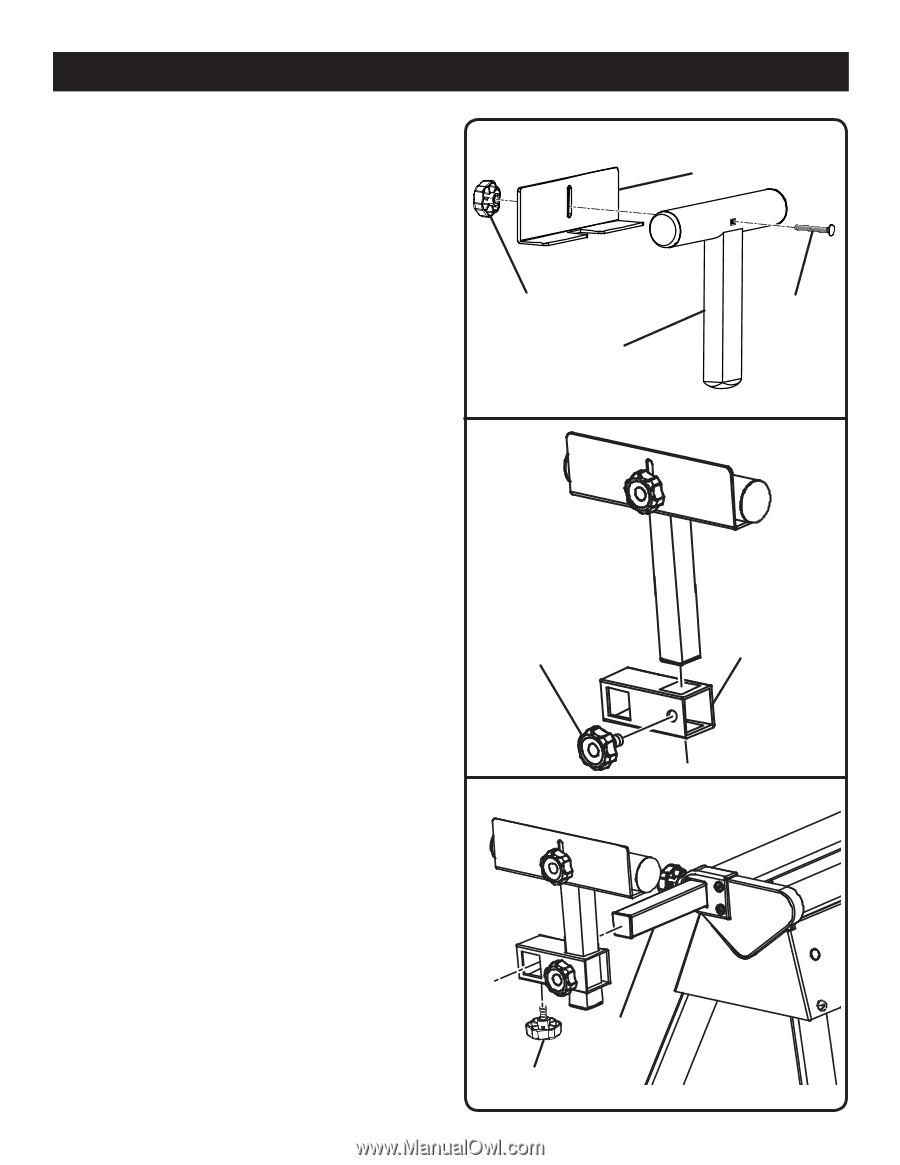

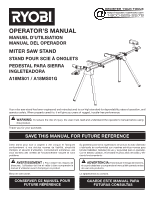

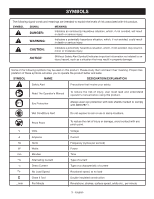

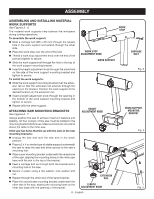

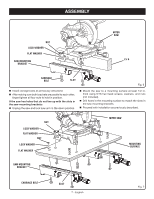

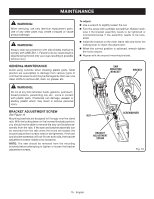

ASSEMBLY ASSEMBLING AND INSTALLING MATERIAL WORK SUPPORTS See Figures 3 - 5. The material work supports help balance the workpiece during cutting operations. To assemble the work support: n Slide a carriage bolt (M6 x 60 mm) through the square hole in the work support and extend through the other side. n Place the work stop over the end of the bolt n Thread a work stop adjustment knob over the end of the bolt and tighten to secure. n Slide the work support rail through the hole in the top of the work support mounting bracket. n Insert the height adjustment knob through the small hole on the side of the work support mounting bracket and tighten to secure. To install the work supports: n Slide the work support mounting bracket over the extension rail so that the extension rail extends through the opening in the bracket. Position the work support at the desired location on the extension rail. n Insert a length adjustment knob through the opening in the bottom of the work support mounting bracket and tighten to secure. n Repeat with the other support. ATTACHING SAW MOUNTING BRACKETS See Figures 6 - 7. Always position the saw to achieve maximum balance and stability. All four corners of the saw must be bolted to the mounting brackets before use. Make sure bolts do not extend above the table of the miter saw. If the saw has holes that line up with the slots in the saw mounting brackets: n Unplug the saw and lock the saw arm in the down position. n Place a 2 x 4 or similar type of stable support underneath the saw to raise the saw and allow access to the saw's mounting feet. n Place a saw mounting bracket underneath the raised side of the saw, aligning the mounting holes on the miter saw base with the slot in the top of the bracket. n Feed a carriage bolt up through both the bracket and a mounting hole in the saw. n Secure in place using a flat washer, lock washer and nut. n Repeat through the other end of the same bracket. n Place the second saw mounting bracket underneath the other side of the saw, aligning the mounting holes on the miter saw base with the opening in the bracket. WORK STOP ADJUSTMENT KNOB WORK SUPPORT HEIGHT ADJUSTMENT KNOB EXTENSION RAIL LENGTH ADJUSTMENT KNOB 6 - English WORK STOP CARRIAGE BOLT Fig. 3 WORK SUPPORT MOUNTING BRACKET Fig. 4 Fig. 5