Ryobi DP102L English Manual - Page 24

Troubleshooting - motor

|

View all Ryobi DP102L manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

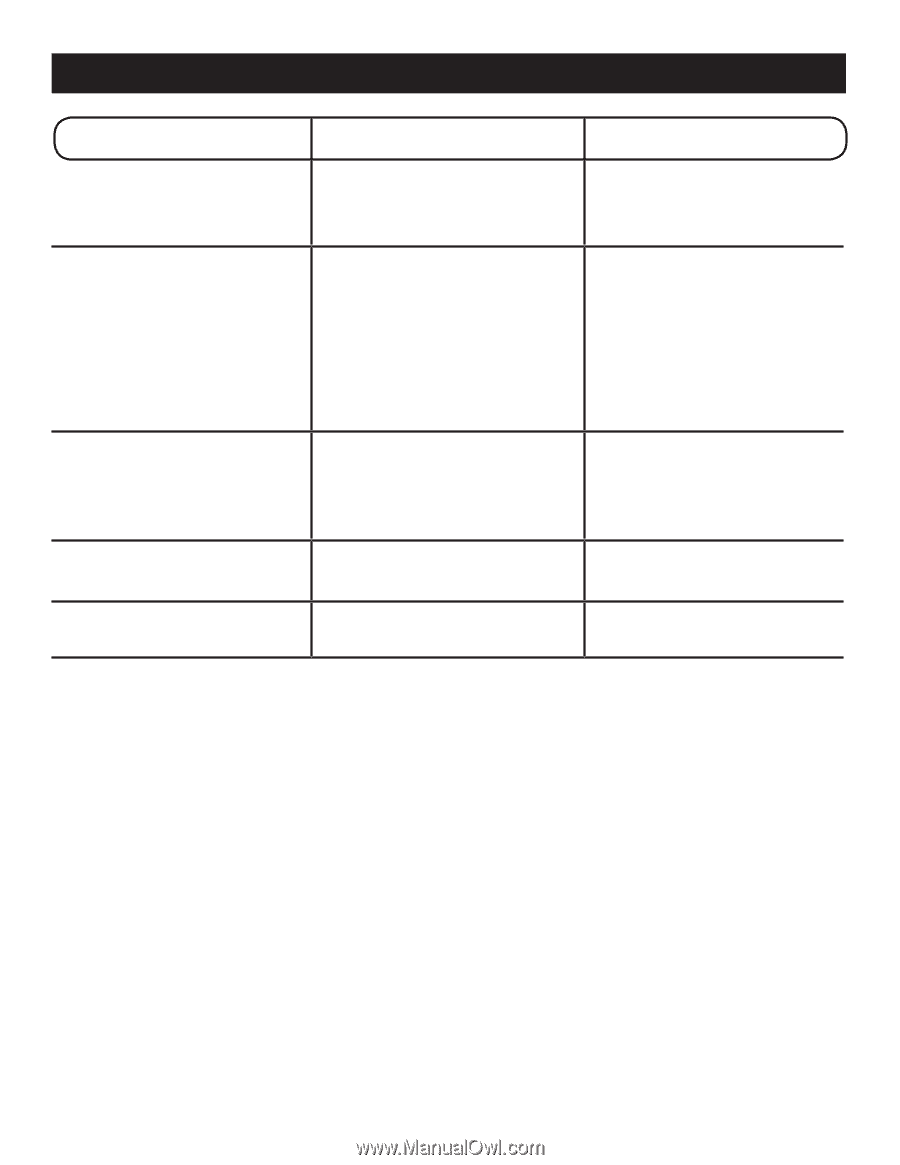

troubleshooting Problem Noisy operation Bit burns or smokes Excessive drill runout or wobble Drill bit binds in workpiece Workpiece support loosens Possible Cause Solution Incorrect belt tension Dry spindle Loose spindle pulley or motor pulley Adjust belt tension. Lubricate spindle. Tighten set screws in pulleys. Incorrect speed Chips not coming out of hole Dull bit Feeding too slow Not lubricated Change speed. See Changing Speeds in the Adjustments section of this manual. Retract bit frequently to clear chips. Sharpen or replace bit. Feed fast enough; allow drill to cut. Lubricate bit for metal work. Bent bit Bit not properly installed in chuck Chuck not properly installed Worn spindle bearings Replace bit. Install bit properly. Install chuck properly. Contact authorized service center. Excessive feed pressure Improper belt tension Reduce feed pressure. Adjust belt tension. Workpiece not supported or clamped Check support and/or reclamp properly workpiece. 24