Ryobi TS1345L User Manual - Page 27

Making An Auxiliary Fence

|

View all Ryobi TS1345L manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

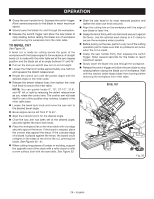

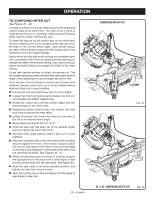

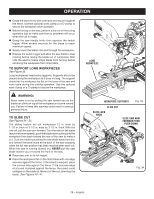

OPERATION When cutting long pieces of lumber or molding, support the opposite end of the stock with a roller stand or with a work surface level with the saw table. See Figure 33. Align the cutting line on the workpiece with the edge of saw blade or laser line. Loosen the slide lock knob by turning the knob counterclockwise. Grasp the stock firmly with one hand and secure it against the fence. Use the work clamp or a C-clamp to secure the workpiece when possible. Before turning on the saw, perform a dry run of the cutting operation to make sure that no problems will occur when the cut is made. With the saw off, grasp the saw handle firmly then pull the saw forward until the blade arbor (center of the saw blade) is over the front of the workpiece or until the saw is fully extended. Squeeze the switch trigger. Allow several seconds for the blade to reach maximum speed. Slowly lower the blade into and through the front edge of the workpiece. Push the saw handle away from you and toward the bevel scale at the back of the saw. Release the switch trigger and allow the saw blade to stop rotating before raising the blade out of workpiece and removing the workpiece from miter table. NOTE: A cross cut is made by cutting across the grain of the workpiece. A straight cross cut is made with the miter table set at the 0° position. Miter cross cuts are made with the miter table set at some angle other than 0°. MAKING AN AUXILIARY FENCE See Figure 36. Certain unusual cuts may benefit from a thicker miter fence (auxiliary fence) due to the size and position of the workpiece. The holes provided in the miter fence are there for just this purpose. The miter fence holes are used to secure the auxiliary fence which requires a piece of wood 1/2 in. thick, 3-1/2 in. high, and 23 in. long to make. NOTE: The auxiliary fence can only be used when the bevel is set at 0°. When making a bevel cut, the auxiliary fence MUST be removed. To attach the auxiliary fence to the saw: Place the wood against the miter fence and mark the hole location from behind the fence using a pencil. Drill holes through the wood then countersink the holes on the front of the wood. Secure the wood to the miter fence using flat head screws. With the miter table set at 0°, make a complete cut through the auxiliary fence to create the blade slot. NOTE: Check for interference between the auxiliary fence and the lower blade guard. Correct any interference before proceeding. Make a full 45° left miter cut and a 45° right miter cut through the completed auxiliary fence. SLIDE CUT PUSH BACK AUXILIARY FENCE Fig. 35 27 − English Fig. 36