ViewSonic PJ870 Service Manual - Page 65

applicable product

|

UPC - 766907376319

View all ViewSonic PJ870 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 65 highlights

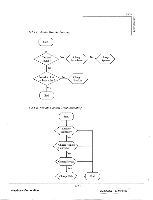

PJ870 IVIINVN TDIAIlaS the warranty period. The required state (light, dark, or non-saturated), restrictions on location within the array, and maximum count of non-functional mirrors are defined only for particular systems, and may be found in the applicable image quality specification. The non-functional mirror defect growth rate shall not exceed 1 per year. The degree of saturation of non-saturated non-functional mirror defects depend both on the particular defect and the system configuration. Note 7 : Blemishes Non-uniformities in the mirror array or optical window may result in localized variations in the luminous output (i.e., blemishes) across the surface of the device when viewed in an optical imaging environment. Such localized non-uniformities may result from a varity of sources, including variations in tilt angles, mirror cupping, foreign particles on the array or inside window surface, window scratches, etc. The magnitude of the projected non-uniformities is highly system dependent. Practicaly speaking, blemishes arising from window defects will be of a common size which depends critically on the system optics. The effect of defect size is generally limited to the differential brightness associated with the defect for scratch, dig and particle defects of practical size. Restrictions on 1 ()cation within the array, maximum count, and differential brightness are defined only for particular systems, and may be found in the applicable product image quality specification. Note 8 : Placement of Active Area within Package The positioning of the die active area within the hermetic package is delineated in Figure 6, Figure 7, and Figure 9. Practical optical systems will need to comprehend a maximum of 0.003" variability in the focal plane of the modulating element referenced to the datum [A], Figure 7 in the absence of any alignment mechanism in the system. if some means of ratational alignment with respect to the system optical axis is comprehended by the design, this variability falls to 0.0014" per Figure 7, datum [K]. The in-plane rotational angle between active area and package datum, Figure 9, note 3 is 0.0 +/- 0.8 degrees. The true position tolerance relative to the package datum is 0.5mm. Note 9 : Window Optical Properties The optical quality of the window is an important contributor to the quality of the projectedimage. To meet the uniformity requirements discussed previously, the minimum window opening defined in Figure 9 must be free of striae, bubbles, inclusions, birefringence, and particles which might degrade the optical performance of the packaged DM1). Visibility of scratch, dig, and particle defects are highly system dependent. The window opening must not block any dump light from the active area. To maximize contrast, the window is coated on both sides by an anti-reflective coating. The average reflectance shall be less than 0.5% for wavelengths of 420-700 nanometers and any angle between normal and 30 degrees. The index of refrection is specified for a light wavelength of 545 nanometers. ViewSonic Corporation [7-5] : Confidential - Do Not Copy