Weider E2000 English Manual - Page 17

Note: The Tap

|

View all Weider E2000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

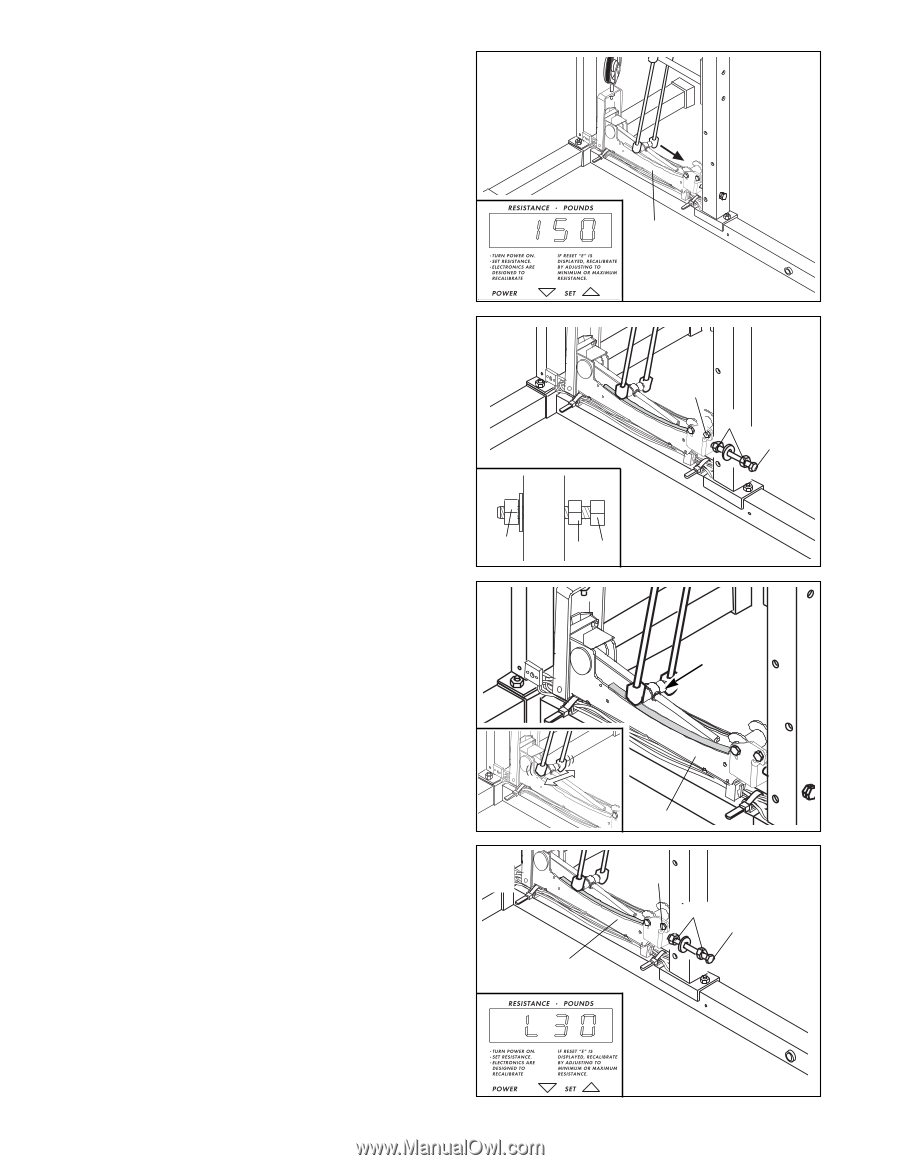

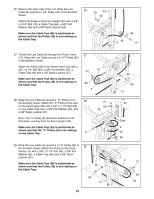

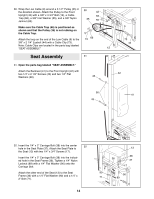

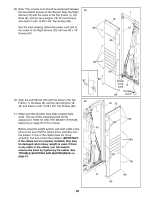

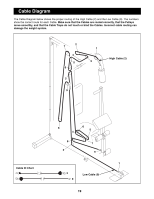

38d.Set the console to 150 pounds as shown in the inset 38d drawing. This will begin to move the Weight Mechanism (26) down. 26 38e.See the inset drawing. Loosen the 3/8Ó Plain Nuts 38e (85), and the 3/8Ó x 3Ó Bolt (88) so that the 3/8Ó x 4Ó Tap Screw (86) can rotate freely. Note: The Tap Screw must pivot freely. 38f. Check the brass piece that is pictured in drawing 38f. It should barely be touching the shaded area on the Weight Mechanism (26) and should move slightly from side to side. 85 If the brass piece is too loose, there will be a noticeable time lapse between the time an exercise is started and the time resistance is felt. If 38f the brass piece is too tight, the Weight Mechan- ism (26) will have difficulty moving and may become jammed so that no movement can occur. 38g.If the brass piece is too loose, tighten the 3/8Ó Tap Screw (86) 1/4 turn. If the brass piece is too tight, loosen the Screw 1/4 turn. Re-check the clearance between the brass piece and the Weight Mechanism (26) after each adjustment until the brass piece is barely touching the shaded area on the Mechanism. It should move slightly from side to side. 38g Begin decreasing the resistance on the console. If the motor stalls or hesitates, loosen the 3/8Ó Tap Screw (86) 1/4 turn. Continue to decrease the resistance until the console is at its lowest weight reading (L30) and the brass piece moves slightly from side to side. When the lowest setting is reached, leave the 3/8Ó Tap Screw (86) stationary and tighten the 3/8Ó Plain Nuts (85) and the 3/8Ó x 3Ó Bolt (88). Disconnect the Power Adapter Cord (connected in step 37) from the wire bundle. 17 88 85 86 85 86 Brass Piece 26 88 85 86 26