GE GTUP240EMWW Installation Instructions - Page 6

Exhaust Information Cont, Exhaust System Check List, Exhaust Information - problems

|

UPC - 084691228998

View all GE GTUP240EMWW manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

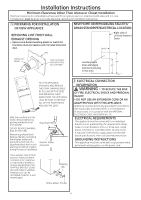

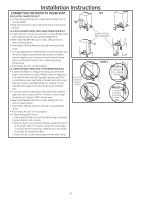

Installation Instructions 3 EXHAUST INFORMATION WARNING - IN CANADA AND IN THE UNITED STATES, THE REQUIRED EXHAUST DUCT DIAMETER IS 4 IN (102mm). DO NOT USE DUCT LONGER THAN SPECIFIED IN THE EXHAUST LENGTH TABLE. Using exhaust longer than specified length will: • Increase the drying times and the energy cost. • Reduce the dryer life. • Accumulate lint, creating a potential fire hazard. The correct exhaust installation is YOUR RESPONSIBILITY. Problems due to incorrect installation are not covered by the warranty. Remove and discard existing plastic or metal foil transition duct and replace with UL listed transition duct . The MAXIMUM ALLOWABLE duct length and number of bends of the exhaust system depends upon the type of duct, number of turns, the type of exhaust hood (wall cap), and all conditions noted below. The maximum duct length for rigid metal duct is shown in the table below. 27" DRYER EXHAUST LENGTH RECOMMENDED MAXIMUM LENGTH Exhaust Hood Types Recommended Use only for short run installations 4" DIA. 4" DIA. 4" DIA. No. of 90º Elbows 0 1 2 3 4" Rigid Metal 56 Feet 46 Feet 34 Feet 32 Feet 2-1/2" Rigid Metal 42 Feet 36 Feet 28 Feet 18 Feet EXHAUST INFORMATION (cont) EXHAUST SYSTEM CHECK LIST HOOD OR WALL CAP • Terminate in a manner to prevent back drafts or entry of birds or other wildlife. • Termination should present minimal resistance to the exhaust air flow and should require little or no maintenance to prevent clogging. •Never install a screen in or over the exhaust duct. This could cause lint build up. • Wall caps must be installed at least 12 in. above ground level or any other obstruction with the opening pointed down. SEPARATION OF TURNS For best performance, separate all turns by at least 4 ft. of straight duct, including distance between last turn and exhaust hood. SEALING OF JOINTS TURNS OTHER THAN 90º • One turn of 45º or less may be ignored. • Two 45º turns should be treated as one 90º turn. • Each turn over 45º should be treated as one 90º turn. • All joints should be tight to avoid leaks. The male end of each section of duct must point away from the dryer. • Do not assemble the ductwork with fasteners that extend into the duct. They will serve as a collection point for lint. • Duct joints can be made air and moisture-tight by wrapping the overlapped joints with duct tape. • Horizontal runs should slope down toward the outdoors ½ inch per foot INSULATION Duct work that runs through an unheated area or is near air conditioning should be insulated to reduce condensation and lint build-up. 24" DRYER EXHAUST LENGTH RECOMMENDED MAXIMUM LENGTH Exhaust Hood Types Recommended Use only for short run installations 4" DIA. 4" DIA. 4" DIA. No. of 90º Elbows 0 1 2 4" Rigid Metal 43 Feet 33 Feet 24 Feet 2-1/2" Rigid Metal 36 Feet 26 Feet 16 Feet 6