Ryobi BT3KIT English Manual - Page 12

Assembly

|

View all Ryobi BT3KIT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

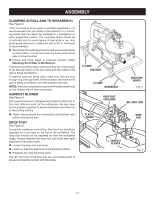

ASSEMBLY UNPACKING This product requires assembly. Carefully remove the product and any accessories from the box. Place it on a level work surface. Inspect the product carefully to make sure no breakage or damage occurred during shipping. Do not discard the packing material until you have care- fully inspected the product, identified all loose parts, and satisfactorily operated the product. If any parts are damaged or missing, please call 1-800-525-2579 for assistance. WARNING: If any parts are damaged or missing, do not operate this product until the parts are replaced. Failure to heed this warning could result in possible serious personal injury. WARNING: Do not attempt to modify this product or create accessories not recommended for use with this product. Any such alteration or modification is misuse and could result in a hazardous condition leading to possible serious personal injury. WARNING: Do not connect to power supply until assembly is complete. Failure to comply could result in accidental starting and possible serious personal injury. WARNING: To avoid serious personal injury, always make sure the saw is securely mounted to a workbench or an approved leg stand. NEVER operate the saw on the floor. REDUCING NOISE AND VIBRATION You may wish to place a foam pad or piece of carpet between the saw base and the workbench to help reduce noise and vibration. If a foam pad or piece of carpet is used, do not overtighten the mounting bolts. Leave some cushion between the padding and the saw base to help absorb the noise and vibration. The size of the padding material should be approximately 24 in. x 12 in. x 1/2 in. MOUNTING SCROLL SAW TO WORKBENCH If the scroll saw is to be used in a permanent application, we recommend that you secure it in a permanent location such as a workbench. When mounting the saw to a workbench, holes should be drilled through the supporting surface of the workbench. Each hole in the base of the saw should be bolted securely using machine bolts, washers, and nuts (not included). Bolts should be of sufficient length to accommodate the saw base, washers, nuts, and the thickness of the workbench. Place scroll saw on workbench. Using the saw base as a pattern, locate and mark the holes where the scroll saw is to be mounted. Drill four holes through the workbench. Place scroll saw on workbench aligning holes in the saw base with the holes drilled in the workbench. Insert all four bolts (not included) and tighten securely with washers and nuts (not included). NOTE: All bolts should be inserted from the top. Install the washers and nuts from the underside of the bench. Supporting surface where scroll saw is mounted should be examined carefully after mounting to insure that no movement during use can result. If any tipping or walking is noted, secure workbench or supporting surface before beginning cutting operations. 12