Ryobi BT3KIT English Manual - Page 19

Operation, Maintenance

|

View all Ryobi BT3KIT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

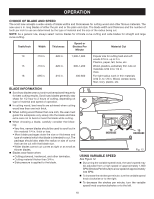

OPERATION SCROLL CUTTING For general type scroll cutting, follow the pattern lines by pushing and turning the workpiece at the same time. Do not try to turn the workpiece while engaged in the blade without pushing it - the workpiece could bind or twist the blade. INTERIOR SCROLL CUTTING See Figure 13. One feature of a scroll saw is that it can be used to make scroll cuts on the interior of a workpiece without breaking or cutting through the edge or perimeter of the board. To make interior cuts in the workpiece, remove the scroll saw blade as explained in the section on Installing Blades. Drill a 1/4 in. hole in the workpiece. Place the workpiece on the saw table with the drilled hole over the access hole in the table. Install blade through the hole in the workpiece; adjust the drop foot and blade tension. When finished making the interior scroll cuts, simply remove the blade from the blade holders as described in the section on Installing Blades. and remove the workpiece from the saw table. STACK CUTTING See Figure 14. After becoming well acquainted with the saw through practice and experience, you may wish to try stack cutting. Stack cutting may be used when several identical shapes need to be cut. Several pieces of wood may be stacked on top and secured to each other before cutting. The wood pieces may be joined together by placing double sided tape between each piece or by wrapping masking tape around the corners or ends of the stacked wood. You must attach the stacked pieces of wood to each other so they will move on the table as a single piece of material. WORKPIECE WOOD PIECES 30 30 DRILL HOLE INTERIOR CUT 15 0 Fig. 13 TAPE 15 0 Fig. 14 MAINTENANCE WARNING: When servicing, use only identical replacement parts. Use of any other parts may create a hazard or cause product damage. WARNING: Always wear safety goggles or safety glasses with side shields during power tool operation or when blowing dust. If operation is dusty, also wear a dust mask. GENERAL MAINTENANCE Avoid using solvents when cleaning plastic parts. Most plastics are susceptible to damage from various types of commercial solvents and may be damaged by their use. Use clean cloths to remove dirt, dust, oil, grease, etc. WARNING: Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating oils, etc., come in contact with plastic parts. Chemicals can damage, weaken, or destroy plastic which may result in serious personal injury. 19