Sharp LC-60LE810UN Service Manual - Page 47

EDID writing Main PWB: QPWBXF452WJZZ, 2. MMAC address writing Main PWB: QPWBXF452WJZZ, 3. Netflix - spec

|

UPC - 074000372580

View all Sharp LC-60LE810UN manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 47 highlights

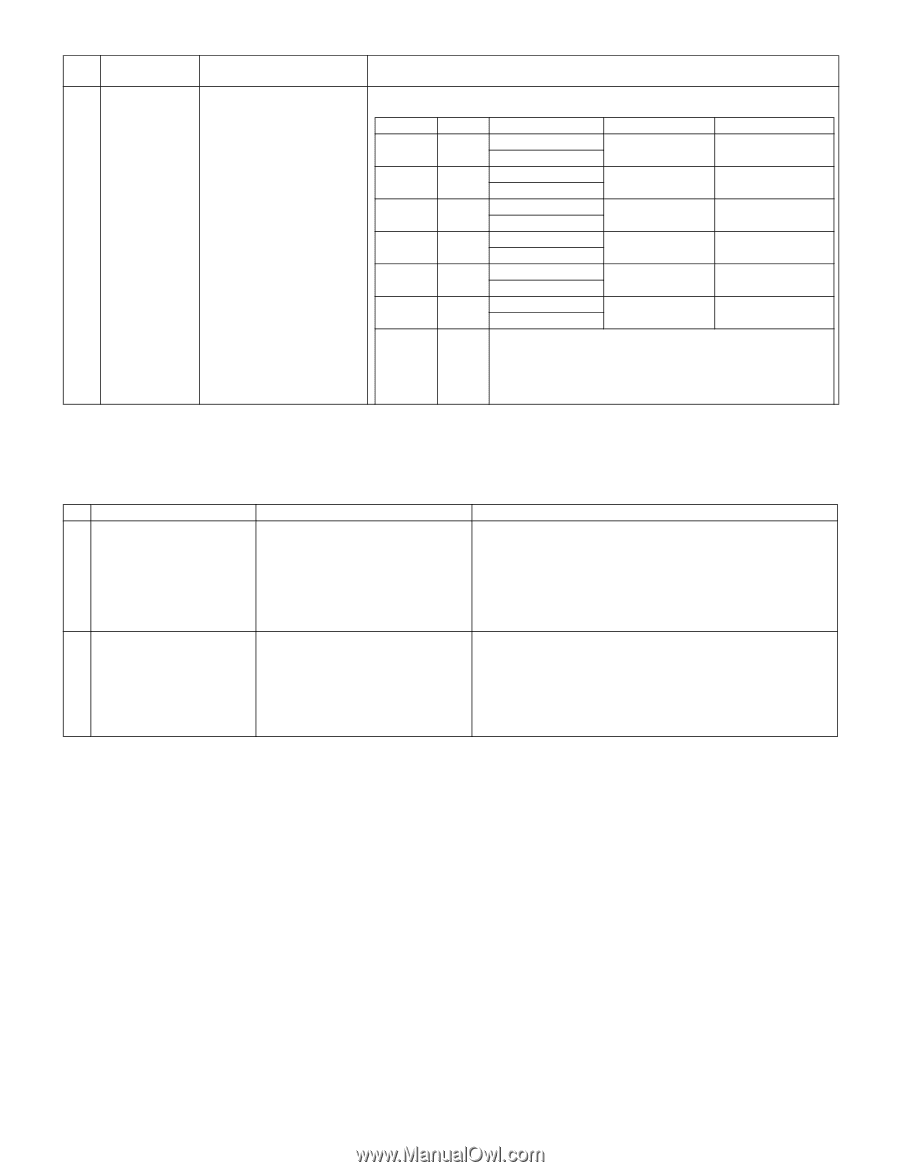

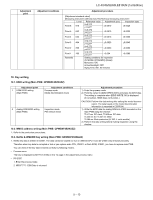

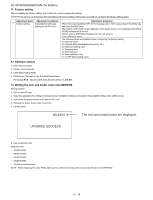

Adjustment point Adjustment conditions LC-40/46/52/60LE810UN (1st Edition) Adjustment procedure [Adjustment standard value] Measuring instrument: [Minolta CA-210] Technical measuring instrument Level Reference value Adjustment spec Inspection spec Point 6 916 X=0.272 y=0.277 ±0.0010 ±0.0020 Point 5 692 X=0.272 y=0.277 ±0.0010 ±0.0020 Point 4 532 X=0.272 y=0.277 ±0.0015 ±0.0030 Point 3 464 X=0.272 y=0.277 ±0.0020 ±0.0040 Point 2 296 X=0.272 y=0.277 ±0.0030 ±0.0060 Point 1 180 X=0.272 y=0.277 ±0.004 ±0.0080 Remarks Setting conditions for inspection AV MODE: [DYNAMIC] (Reset) Monochro: ON Active Backlight: OFF Aging Time: Min. 60 minutes 10. Key writing 10.1. EDID writing (Main PWB: QPWBXF452WJZZ) Adjustment point 1 HDMI EDID writing (Main PWB) Adjustment conditions Process mode Model discrimination check 2 Analog RGB EDID writing (Main PWB) Inspection mode File version check Adjustment procedure 1) Enter the process mode. 2) Point the cursor to [EDID WRITE ENT] and press the [ENT] key. The writing is complete when [EDID WRITE OK] is displayed. (If not written, HDMI does not function.) CAUTION: Perform the data writing after setting the model discrimination. The data based on the model discrimination information is recorded in EEPROM. 1) Write the EDID data for analog RGB into IC509 mounted on the main PWB using the checker. TL511 ••• I2C clock, TL508 ••• I2C data TL544 ••• 5V, TL507 ••• GND TL585 ••• Write protection (H: WP, L: write enable) 2) Perform the data writing before making inspection using the checker. 10.2. MMAC address writing (Main PWB: QPWBXF452WJZZ) 1. Refer to the production precautions. 10.3. Netflix & WMDRM Key writing (Main PWB: QPWBXF452WJZZ) 1. Netflix key data is written in IC8401. The data cannot be copied nor run on different CPU. It can be written only in factory securely. Therefore when key data is corrupted or lost or you replace main CPU, IC8001, or flash ROM, IC8401, you have to replace main PWB. You can check if the key data is stored correctly by following means. • Process menu The key is displayed to [NETFLIX ESN] on the 1st page in the adjustment process menu. • RS-232C 1. Enter the process mode. 2. NFKY???? : ESN Data is returned. 5 - 13