Snapper RE110 Operater's Manual - Page 20

Maintenance, WARNING

|

View all Snapper RE110 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 20 highlights

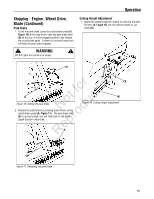

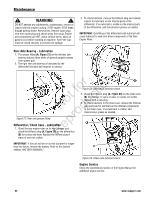

Maintenance Safety Interlock System Checks ! WARNING ! DO NOT operate machine if any safety interlock or safety device is not in place and functioning properly. DO NOT attempt to defeat, modify or remove any safety device. Check Engine 1. Change the engine oil. Refer to the section entitled "CHANGE ENGINE OIL". Refer to the engine manual for oil specifications. 2. Change the air filter: • Pull up and rotate the air cleaner latch (A, Figure 23) to remove the air cleaner cover (B). Engine must not start if: IMPORTANT: When the cover is removed, you are viewing 1. The Clutch/Brake Pedal is not fully depressed OR, the carburetor side of the air filter, which will appear clean. 2. The Blade Control is in the "ON" (blades engaged) posi- Remove the filter and pre-cleaner for inspection. tion. Engine should start if: 1. The Blade Control is in the "OFF" (blades disengaged) A position AND, 2. The Clutch/Brake Pedal is fully depressed. Engine and blades must stop if: C 1. The operator rises off of seat with Blade Control in "ON" (blades engaged) position OR, 2. The operator rises off of seat with Clutch/Brake Pedal not fully depressed. r n Reverse Lockout Mechanism fo tio Check the function of the Reverse Lockout Mechanism with the engine off. 1. Depress and hold the blade pedals. t c 2. Depress and hold the clutch/brake pedal. 3. With Steps 1 and 2 performed, the shift lever must not o u go into reverse. N d ! WARNING ! o DO NOT operate machine if Reverse Lockout Mechanism is r not functioning properly. Contact your SNAPPER dealer immediately for assistance. ep Lubrication - Grease Fittings The following components on the Rear Engine Rider are R equipped with grease fittings and require periodic lubrica- D B Figure 23: Opening the engine air cleaner cover (May vary by model - refer to engine manual) • Remove the air cleaner (C). • Remove and clean the engine air pre-cleaner (located behind the air cleaner). Refer to the engine manual for cleaning and service instructions. • Install the pre-cleaner and replace the air cleaner per the engine manual. • Reinstall the air cleaner cover. Engage the latch over the cover and rotate and push down to lock. IMPORTANT: The tabs (D) on the air cleaner cover must be completely inserted into the corresponding slots in the tion. Apply General Purpose grease (NLGI No.2) with a engine cover, or the compartment will not be completely grease gun. sealed to prevent debris from entering into the carburetor. 1. Front Wheel Bearings. Refer to the section entitled "FRONT WHEEL BEARINGS - LUBRICATION". 2. Rear Axle Bearing. Refer to the section entitled "REAR AXLE BEARING - LUBRICATION". 3. Mower Blade Spindle. Refer to the section entitled "MOWER BLADE SPINDLE - LUBRICATION". 4. Shift Lever. Refer to the section entitled "SHIFT LEVER - LUBRICATION". 20 www.snapper.com