Brother International BAS-300 Series Programmer Instruction Manual - English - Page 11

Emblem, Sewing

|

View all Brother International BAS-300 Series manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

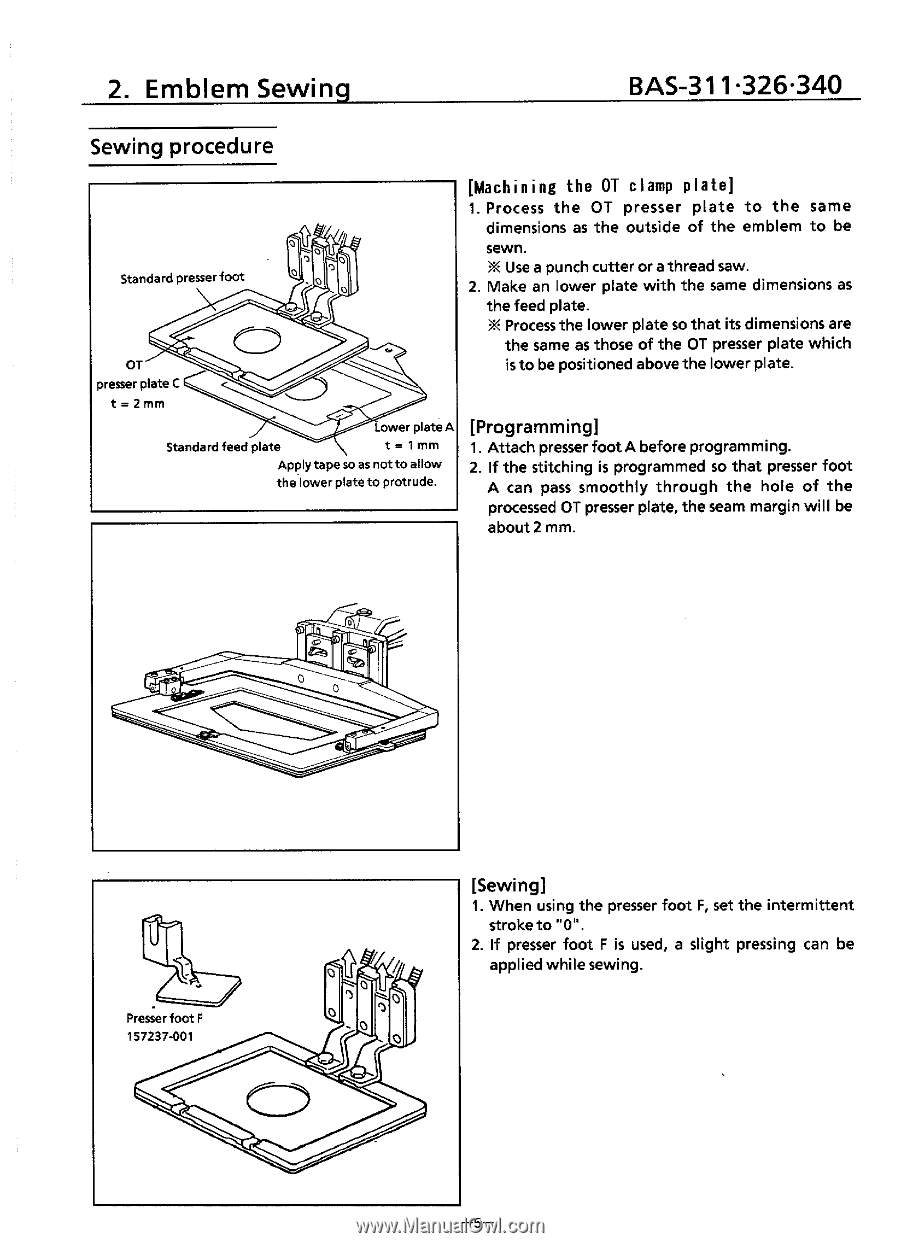

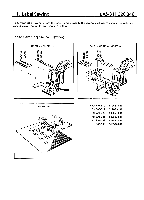

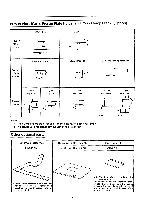

2. Emblem Sewing BAS-311.326340 Sewing procedure Standard presser foot 0 or 0 0 0 0 0 0 0 0 [Machining the OT clamp plate] 1. Process the OT presser plate to the same dimensions as the outside of the emblem to be sewn. X Use a punch cutter or a thread saw. 2. Make an lower plate with the same dimensions as the feed plate. X Process the lower plate so that its dimensions are the same as those of the OT presser plate which is to be positioned above the lower plate. presser plate C t = 2 mm Lower plate A Standard feed plate t = 1 mm Apply tape so as not to allow the lower plate to protrude. [Programming] 1. Attach presser foot A before programming. 2. If the stitching is programmed so that presser foot A can pass smoothly through the hole of the processed OT presser plate, the seam margin will be about 2 mm. 0 0 Presser foot F 157237-001 0 0 0 0 0 0 0 [Sewing] 1. When using the presser foot F, set the intermittent stroke to "0". 2. If presser foot F is used, a slight pressing can be applied while sewing. -5-