Brother International BAS-300 Series Programmer Instruction Manual - English - Page 21

There, Dimension, Differences

|

View all Brother International BAS-300 Series manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

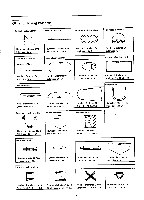

........ If There Are Dimension Differences [Work Clamp] 1) Process the work clamp plate to match the dimensions of the breast pocket. 2) If thin rubber or sand paper is stuck to the lower surface of the work clamp blank, then the material will be firmly clamped and sewing can be carried out easily. Thin rubber (Example) Shunting point Start poi End A Shunting point Start point 666E [Programming] Use a split program. Enter a shunt feed (F) from the final stitch position in seam A to the initial stitch position in seam B, and then enter 666 O at that start point. End 0 0 0 0 0 A B Thin rubber [Sewing] 1) This program enables the presser foot to be lifted at B to reconfirm the position of the material. The sewing procedure is sew A, move to the shunting point at B, and stop the sewing machine. Raise the clamp to check the material position and then restart the machine. Seam B will be sewn, and after the machine returns to the shunting point at A, it will stop and the clamp will be raised. 2) When setting the material, adjust the DIP switch located on the circuit board or modify the air tube so that the clamp can be provided with two-stage positioning. * Two-stage positioning unit • If the clamp foot switch (SW) is pressed to the first stage, air will be released from the clamp cylinder, and the clamp will be lowered by the spring force. Because the clamp does not press the material at this time (floating by 1 to 2 mm), the material can be moved freely and set in the specified position. • If the foot switch is pressed to the second stage, air enters the cylinder, and the clamp will press the material firmly. (Refer to p. 6) -15-