Canon PIXMA iP1500 Service Manual - Page 14

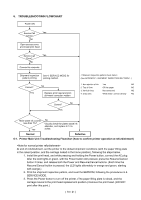

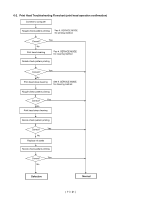

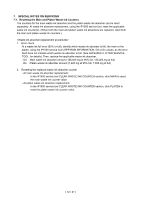

Product Technical Information - paper jam

|

View all Canon PIXMA iP1500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

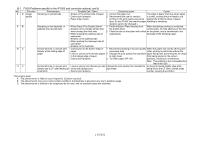

8. PRODUCT TECHNICAL INFORMATION 8-1. FAQ (Problems specific to the iP1500 and corrective actions) No. * Function Phenomenon Possible Call / Claim Corrective action Cause 1 A Installation Carriage error (LED blinks - LED blinks alternately in orange and Remove the packing material fixing the The user may not have removed the alternately in orange and green 2 green, 2 times (carriage error). carriage. packing material at unpacking and times). installation. Although a caution sheet is packaged together with the printer, the user may not have noticed it. Note: Even if the packing material remains, no parts are damaged. 2 A Ink tank installation error - LED blinks in orange 4 times (ink Open the access cover, and install the ink Since the user did not seat the ink tanks (LED blinks in orange 4 times.) tank installation error). (As this tanks properly. completely at unpacking, installation, or occurs at printer installation, the user ink tank replacement, the ink tank cannot recognize the error.) contacts the main case. 3 B Paper feeding No paper feeding when a number of sheets are loaded. (PP-101) - Paper out error - Paper cannot be fed - Cannot print 4 B Multi-feeding - Multiple pages of paper are fed simultaneously. -Blank paper is ejected. 5 B Envelope not feeding - Paper out error - Paper cannot be fed - Cannot print 6 B 7 C Envelope jam at feeding Paper jam - Paper jam error - Paper cannot be fed - Cannot print - Paper jam error - Paper cannot be fed - Cannot print 1. Perform roller cleaning from the printer The paper feed roller slips on the paper at driver. paper feeding. 2. Clean the paper feed roller with pre-moistened wipe or moistened cloth. 1. Fan the paper and set them in the In the high temperature and high humidity ASF. environment, the frictional force between 2. In case of PR-101, set the paper sheet the front and back sides of paper by sheet in the ASF. becomes high, and sheets stick to each other, contributing to multi-feeding. 1. Perform roller cleaning from the printer The paper feed roller slips on the paper at driver. paper feeding. 2. Clean the paper feed roller with Note: Depending on the paper lots. This pre-moistened wipe or moistened phenomenon may occur in DL cloth. envelope. 3. Reduce the number of envelopes loaded in the ASF. 4. Flatten the envelope (with a pen). 1. Perform roller cleaning from the printer When the paper is fed by the driver. slightly-slippery paper feed roller, the flap 2. Reduce the number of envelopes is caught in the return position of the claw. loaded in the ASF. 1. Remove the jammed paper from the As the LF roller slips on the paper, the paper pick-up side. paper is not fed, causing the jam error at paper ejecting. ( 14 /21)