Craftsman 16781 Owners Manual - Page 22

Clean or replace. See Air Filter

|

View all Craftsman 16781 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

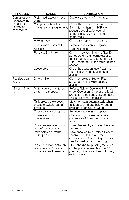

PROBLEM Compressor is not supplying enough air to operate accessories Restricted air intake Motor will not run CAUSE CORRECTION Prolonged excessive use Decrease amount of air usage. of air. Compressor is not large enough for air requirement. Hole in hose. Check the accessory air requirement. If it is higher than the SCFM or pressure supplied by your air compressor, you need a larger compressor. Check and replace if required. Check valve restricted. Air leaks. Restricted air intake filter. Loose belt. Remove and clean, or replace. Tighten fittings. Clean or replace air intake filter. Do not operate the air compressor with the filter removed. Refer to the "Air Filter" paragraph in the Maintenance section. Check belt tension, see Adjusting Belt Tension in the Maintenance section. Dirty air filter. Motor overload protection switch has tripped. Clean or replace. See Air Filter paragraph in the Maintenance section. Refer to "Motor Overload Protection" under Operation. If motor overload protection trips frequently, contact a Trained Service Technician Tank pressure exceeds )ressure switch "cut-in" )ressure. Check valve stuck open. Loose electrical connections. Possible defective motor or starting capacitor. Paint spray on internal motor parts. Pressure release valve on pressure switch has not unloaded head pressure. Motor will start automatically when tank pressure drops below "cut-in" )ressure of pressure switch. Remove and clean, or replace. Check wiring connection inside pressure switch and terminal box area. Have checked by a Trained Service Technician. Have checked by a Trained Service Technician. Do not operate the compressor in the paint spray area. See flammable vapor warning. Bleed the line by pushing the lever on the pressure switch to the "Off" position; if the valve does not open, replace switch. 1000002023 22 ENG