Craftsman 21829 Operation Manual - Page 9

Feetperminuteor, usedin, toblade, Thenumberof, completed, aspinning - table saw

|

View all Craftsman 21829 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

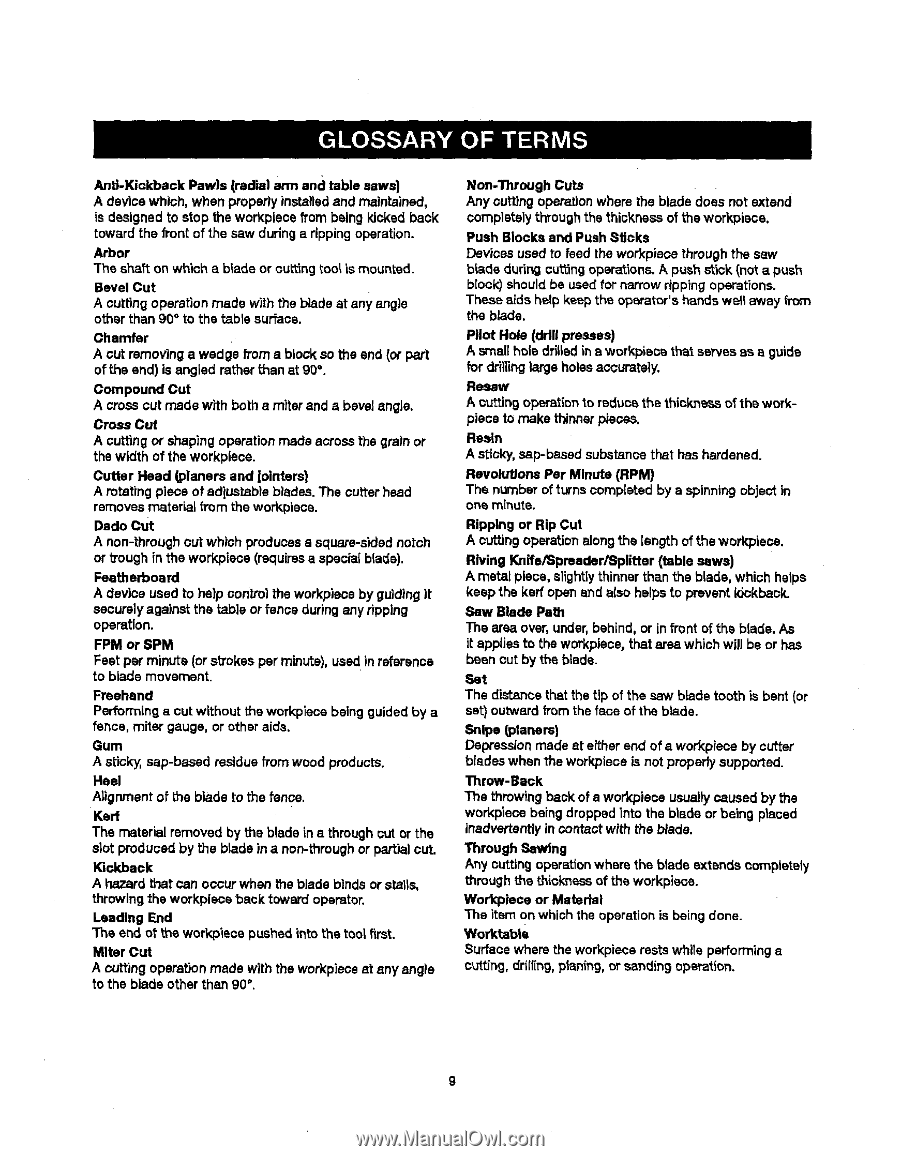

Anti-Kickback Pawla (radial arm and table saws) A device which, when properlyinstalledand maintained, is designed to stop the wcrkpisee from being kicked back toward the front of the saw duringa rippingoperation. Arbor "Theshaft on which a brads or cu_}ng tool is mountsd. Bevel Cut A cutting operation made w]th the blade at any angle other than 90° to the table surPace. Chamfer A cut removing a wedge from a blockso the end (or part of the and) is angled ratherthan at go°_ Compound Cut A cross out made with bert1a miter and a bevelangle. Cross Cut A cutting or shap]ng operation made across the grain or the width of the workpisce. Cutter Head (planers and Jointera| A rotatingpiece of ad}ustabla blades. The cutter head removes material from the warkpiece. Dedo Cut A non-throughcut which producesa square-sided notch or bough in the workplece (requiresa special blade). Featharboard A device used to help centre] the workpless by guidingit securelyagainst the table or fence duringany ripping operation. FPM or $PM Feetperminute(orstrokesperminute)u,sedinreference toblademovement. Freehand Performinga cut without the workpiece being guided by a fence, miter gauge, or other aide. Gum A stick'34s,ap-based residue from wood products. Heel Alignment of the blade to the fence. Karl The material removed by the blade In a throughcut or the slot produced by the b!ade in a non-throughor partial cut. Kickback A hazard that can occur when the blade binds or stalls, throwingthe workplace back toward operator. Leading End "Theend of the workp'lecepushed into the tool first. Mltar Cut A cutting operation made with the workplace at any angle to the blade other than 90 °. Non-Through Cuts Any cutting operationwhere the blade does not extend completelythrough the thickness of the workplace, Push Blocks and Push 8ticks Devices used to feed the workpiece through the saw biade duringcutting operations.A push stick (not a push Mock) should be usedfor narrow ripping operations. These aids help keep the operator'shands w_l away frccn the blade. Pilot Hole (drill presses) A small hole drilled in a workpie_ that serves as a guide for drillinglarge holes accurately. Reeaw A cutting operetiento reduoathe thickness of the workpiece to make thinnerpieces, Resin A sticky,sap-based substancethat has hardened. Revolutions Par Minute {RPM) The number ofturnscompletedby a spinningobjectin one minute. Ripping or Rip Cut A cutting operationalongme length of the work.piece. Riving Knifa/_prsader/Splittar (table saws} A metal piece, slightly thinnerthan the blade, which helps keep the kerr open and a{sa helpsto prevent k.Jckback. Saw Blade Path The area over, under,behind, or in front of the blade. As it applies to the workplece,that area which will be or has been cut by the blade. Sat The distancethat the tip of the saw blade tooth is bent (or set:}outward from the face of the blade. Snipe (planers) Depression made at e_her end ofa workplace by cutter blades when the workplace is not properlysupported. Throw-Back The throwing back of a worl(plece usuallycaused by the workplace being dropped into the blade or being placed inadvertentlyin contact with the blade. Through SaWing Any cutting operationwhere the blade extends completely through the thickness of the workplace. Workplace or Materiel The item On which the operation is being done. Worktabta Surface where the work.piecerests white performinga cutting, drilling,planbg, or sanding operation. g