Electrolux EIGD55IKG Installation Instructions - Page 5

Installation, Requirements - appliances

|

UPC - 012505379710

View all Electrolux EIGD55IKG manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

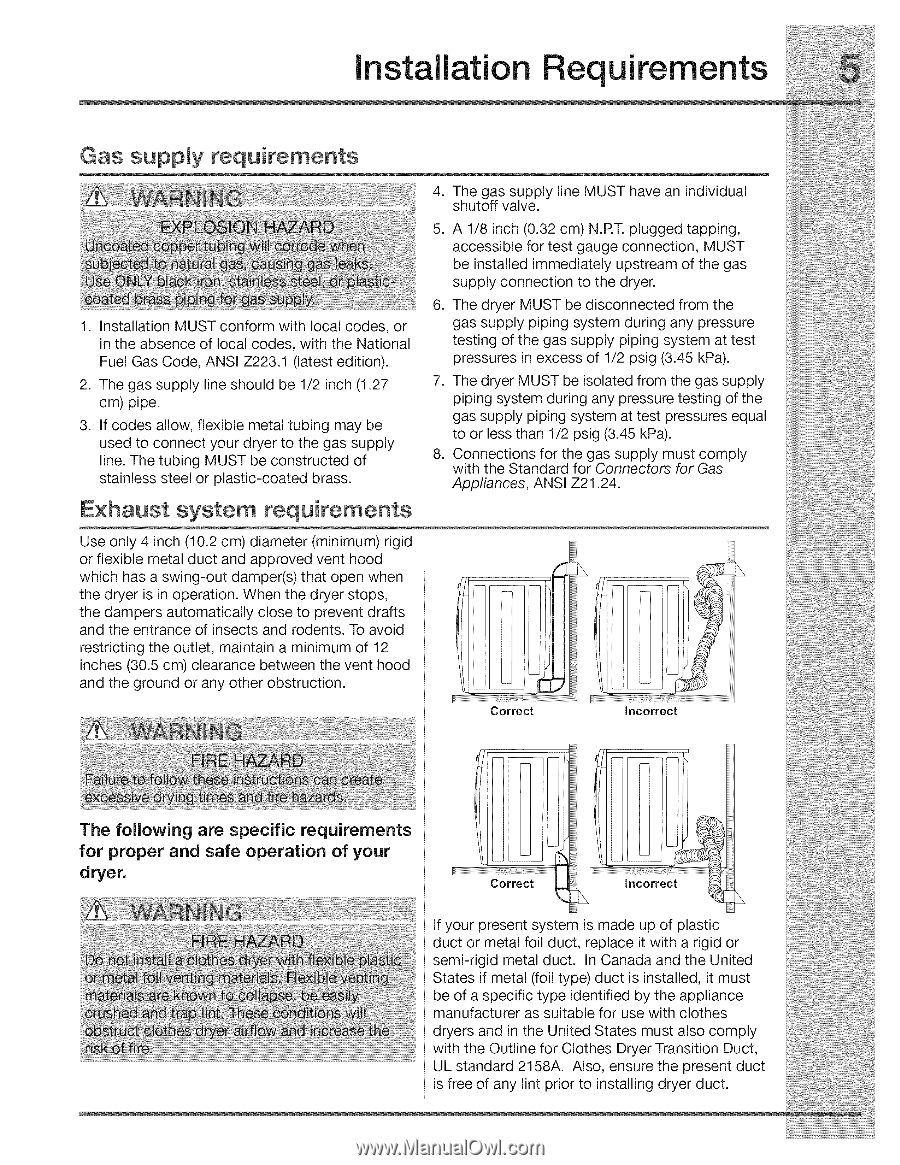

Installation Requirements Gas supply requirements 1. Installation MUST conform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1 (latest edition). 2. The gas supply line should be 1/2 inch (1.27 cm) pipe. 3. If codes allow, flexible metal tubing may be used to connect your dryer to the gas supply line. The tubing MUST be constructed of stainless steel or plastic-coated brass. Exhaust system requirements Use only 4 inch (10.2 cm) diameter (minimum) rigid or flexible metal duct and approved vent hood which has a swing-out damper(s) that open when the dryer is in operation. When the dryer stops, the dampers automatically close to prevent drafts and the entrance of insects and rodents. To avoid restricting the outlet, maintain a minimum of 12 inches (30.5 cm) clearance between the vent hood and the ground or any other obstruction. . The gas supply line MUST have an individual shutoff valve. 5. A 1/8 inch (0.32 cm) N.RT. plugged tapping, accessible for test gauge connection, MUST be installed immediately upstream of the gas supply connection to the dryer. 6. The dryer MUST be disconnected from the gas supply piping system during any pressure testing of the gas supply piping system at test pressures in excess of 1/2 psig (3.45 kPa). 7. The dryer MUST be isolated from the gas supply piping system during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.45 kPa). 8. Connections for the gas supply must comply with the Standard for Connectors for Gas Appliances, ANSI Z21.24. Correct Incorrect The following are specific requirements for proper and safe operation of your dryer. If your present system _smade up of plastic duct or metal foil duct, replace it with a rigid or semi-rigid metal duct. In Canada and the United States if metal (foil type) duct is installed, it must be of a specific type identified by the appliance manufacturer as suitable for use with clothes dryers and in the United States must also comply with the Outline for Clothes Dryer Transition Duct, UL standard 2158A. Also, ensure the present duct is free of any lint prior to installing dryer duct.