GE JVM1790SK Service Manual - Page 30

B. Checkout Procedures - problems

|

UPC - 084691123453

View all GE JVM1790SK manuals

Add to My Manuals

Save this manual to your list of manuals |

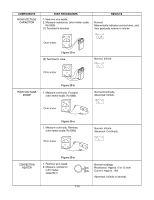

Page 30 highlights

COMPONENTS RELAY 2 TEST PROCEDURES 1. Measure continuity. (ohm meter scale: Rx1) 2. Remove the lead wires and operate oven at power level 1 through power level 10. RELAY 11 1. Measure continuity. (ohm meter scale: Rx1) 2. Remove the lead wires and operate oven at Convection Cooking. POWER LEVEL 1 2 3 4 5 6 7 8 9 10 RESULTS 4 sec 6 sec 8 sec 10 sec 12 sec 14 sec 16 sec 18 sec 20 sec 22 sec 18 sec 16 sec 14 sec 12 sec 10 sec 8 sec 6 sec 4 sec 2 sec 0 Convection OFF Cooking Start NOTES: • A MICROWAVE ENERGY TEST MUST ALWAYS BE PERFORMED WHEN THE UNIT IS SERVICED FOR ANY REASON. • MAKE SURE THE WIRE LEADS ARE IN THE CORRECT POSITION. • WHEN REMOVING THE WIRE LEADS FROM THE PARTS, BE SURE TO GRASP THE CONNECTOR, NOT THE WIRES. B. CHECKOUT PROCEDURES (1) CHECKOUT PROCEDURES FOR FUSE BLOWING CAUTION: REPLACE BLOWN FUSE WITH 20 AMPERE FUSE. PROBLEMS Fuse blows immediately after the door is closed. Fuse blows immediately after the door is opened. Fuse blows when the door is closed and START key is touched. CAUSES Improper operation of the primary interlock, secondary interlock switches and/or the interlock monitor switch. Malfunction of the high voltage transformer; the high voltage capacitor including the diode, the magnetron, the blower motor or the circuit board. NOTES: • If the fuse is blown by an improper switch operation, replace the all Interlock switches, PCB Ass'y and the fuse at the same time. After replacing the the all Interlock switches, PCB Ass'y,Fuse with new ones, make sure that they are correctly connected. • Check for microwave energy leakage according to INTERLOCK ADJUSTMENT PROCEDURES on page 712 when the primary interlock, secondary interlock switches and/or the interlock monitor switches are adjusted or replaced. 7-19