HP Indigo WS6600 Working with Indigo ElectroInk Invisible Yellow and Blue for - Page 6

UV properties of the HP Indigo ElectroInk Invisible Yellow and Blue, BID Engage

|

View all HP Indigo WS6600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

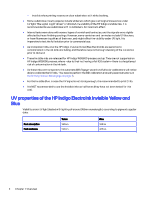

- Invisible when printing reverse on clear substrates, with white backing. ● Some substrates (mostly papers) include whiteners which give a strong luminescence under UV light. This signal might "drown" or diminish the visibility of the HP Indigo invisible inks. It is recommended to use substrates with no whiteners, for maximum effect. ● Internal tests were done with several types of varnish and laminates, and the signals were slightly affected by these finishing coatings. However, some varnishes and laminates include UV blockers, or have fluorescent qualities of their own, and might affect the visibility under UV light. It is imperative to test the full solution prior to commercial use. ● As transparent inks, also the HP Indigo Invisible Yellow/Blue ElectroInks are sensitive to contamination in the ink tank and tubing, and therefore require thorough cleaning of the ink station prior to ink build. ● These Invisible inks are released for HP Indigo WS6600 presses and up. They are not supported on HP Indigo WS6000 presses, where -due to their not having a full IOS system- there is a heightened risk of contamination in the ink tank. ● As these inks are transparent, the automaticBID Engage wizard and full color calibrations will not be able to calibrate the UV inks - You need to perform the BID calibration manually (see instructions in Performing manual BID engage on page 7). ● For the Invisible Blue, in case the UV signal is not strong enough, it is recommended to print 2 hits. ● It is NOT recommended to use the Invisible inks as half tones (they have not been tested for this use). UV properties of the HP Indigo ElectroInk Invisible Yellow and Blue Visibility under UV light (tested with lighting of around 365nm wavelength), according to pigment supplier data: Peak absorption Peak emission Yellow 393nm 548nm Blue 345nm 465nm 2 Chapter 1 Overview