Hitachi C12RSH User Guide - Page 62

Mounting And Dismounting Saw Blade - set up

|

UPC - 717709010345

View all Hitachi C12RSH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 62 highlights

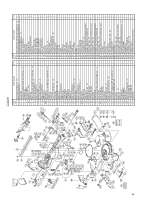

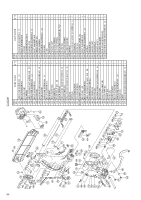

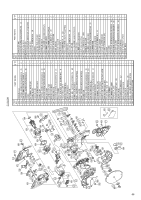

English To install the stopper, attach it to the holder with the 6 mm knob bolt as shown in Fig. 28. 24. Confirmation for use Crown molding vise, Crown molding Stopper (L) and (R) (Optional accessory) (1) Crown molding Stopper (L) and (R) (optional accessories) allow easier cuts of crown molding without tilting the saw blade. lnstall them in the base both-sides side to be shown in Fig. 29. After inserting tighten the 6 mm knob bolts to secure the Crown molding Stoppers. (2) The crown molding vise (B) (Optional accessory) can be mounted on either the left fence (Fence (B)) or the right fence (Fence (A)). lt can unite with the slope of the crown molding and vice can be pressed down. Then turn the upper knob, as necessary, to securely attach the crown molding in position. To raise or lower the vise assembly, first loosen the 6 mm knob bolt. After adjusting the height, firmly tighten the 6 mm wing bolt; then turn the upper knob, as necessary, to securely attach the the crown molding in position (Fig 30). Position crown molding with its WALL CONTACT EDGE against the guide fence and its CEILING CONTACT EDGE against the Crown molding Stoppers as shown in Fig. 30. Adjust the Crown molding Stoppers according to the size of the crown molding. Tighten the 6 mm wing bolt to secure the Crown molding Stoppers. Refer to the lower table for the miter angle. Use the sub fence (A) to secure the crown molding more firmly (Fig. 11). WARNING Always firmly clamp or vise to secure the crown molding to the fence; otherwise the crown molding might be thrust from the table and cause bodily harm. Do not bevel cutting. The main body or saw blade may contact the sub fence, resulting in an injury. CAUTION Always confirm that the motor head (Fig. 1) does not contact the crown molding vise ass'y when it is lowered for cutting. If there is any danger that it may do so, loosen the 6mm knob bolt and move the crown molding vise ass'y to a position where it will not contact the saw blade. 25. Groove cutting procedures Grooves in the workpiece can be cut by adjusting the 6 mm depth adjustment bolt (Fig. 32). (1) Turn the stopper holder on the direction shown in Fig. 32. Lower the motor head, and turn the 6 mm depth adjustment bolt by hand. (Where the head of the 6 mm depth adjustment bolt contacts the hinge.) (2) Adjust to the desired cutting depth by setting the distance between the saw blade and the surface of the base (Fig. 31). NOTE When cutting a single groove at either end of the workpiece, remove the unneeded portion with a chisel. MOUNTING AND DISMOUNTING SAW BLADE WARNING ⅜ To prevent an accident or personal injury, always turn off the trigger switch and disconnect the power plug from the receptacle before removing or installing a saw blade. 61 If cutting work is done in a state where the 10 mm bolt is not sufficiently tightened, the 10 mm bolt can get loose, the blade can come off, and the lower guard can get damaged, resulting in injuries. Also, check that the 10 mm bolts are properly tightened before plugging the power plug into the receptacle. ⅜ If the 10 mm bolts are attached or detached using tools other than the 17 mm box wrench (standard accessory), excessive or improperly tightening occurs, resulting in injury. 1. Mounting the saw blade (Fig. 33, Fig. 34, Fig. 35 and Fig. 36) (1) Use the Phillips screwdriver to loosen the 5 mm screw fastening the spindle cover and then turn the spindle cover. (2) Press in spindle lock and loosen 10 mm bolt with 17 mm box wrench (standard accessory). Since the 10 mm bolt is left-hand threaded, loosen by turning it to the right as shown in Fig. 35. NOTE If the spindle lock cannot be easily pressed in to lock the spindle, turn the 10 mm bolt with 17 mm box wrench (standard accessory) while applying pressure on the spindle lock. The saw blade spindle is locked when the spindle lock is pressed inward. (3) Remove the bolt and washer (D) (4) Lift the lower guard and mount the saw blade. WARNING When mounting the saw blade, confirm that the rotation indicator mark on the saw blade and the rotation direction of the gear case (Fig. 1) are properly matched. (5) Thoroughly clean washer (B) and the 10 mm bolt, and install them onto the saw blade spindle. (6) Press in the spindle lock and tighten the 10 mm bolt by turning it to the left by standard accessories (17 mm box wrench) as indicated in Fig. 35. CAUTION ⅜ A dust guide is installed inside behind the hinge. When removing or installing the saw blade, do not make contact with the dust guide. Contact may break or chip saw blade tips. ⅜ Confirm that the spindle lock has returned to the retract position after installing or removing the saw blade. ⅜ Tighten the 10 mm bolt so it does not come loose during operation. Confirm the 10 mm bolt has been properly tightened before the power tool is started. 2. Dismounting the saw blade Dismount the saw blade by reversing the mounting procedures described in paragraph 1 above. The saw blade can easily be removed after lifting the lower guard. CAUTION Never attempt to install saw blades except 290 mm - 305 mm in diameter.