Hitachi NR90GC Service Manual - Page 31

DISASSEMBLY AND REASSEMBLY, 10-1. General Precautions in Disassembly and Reassembly - parts list

|

UPC - 717709008533

View all Hitachi NR90GC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 31 highlights

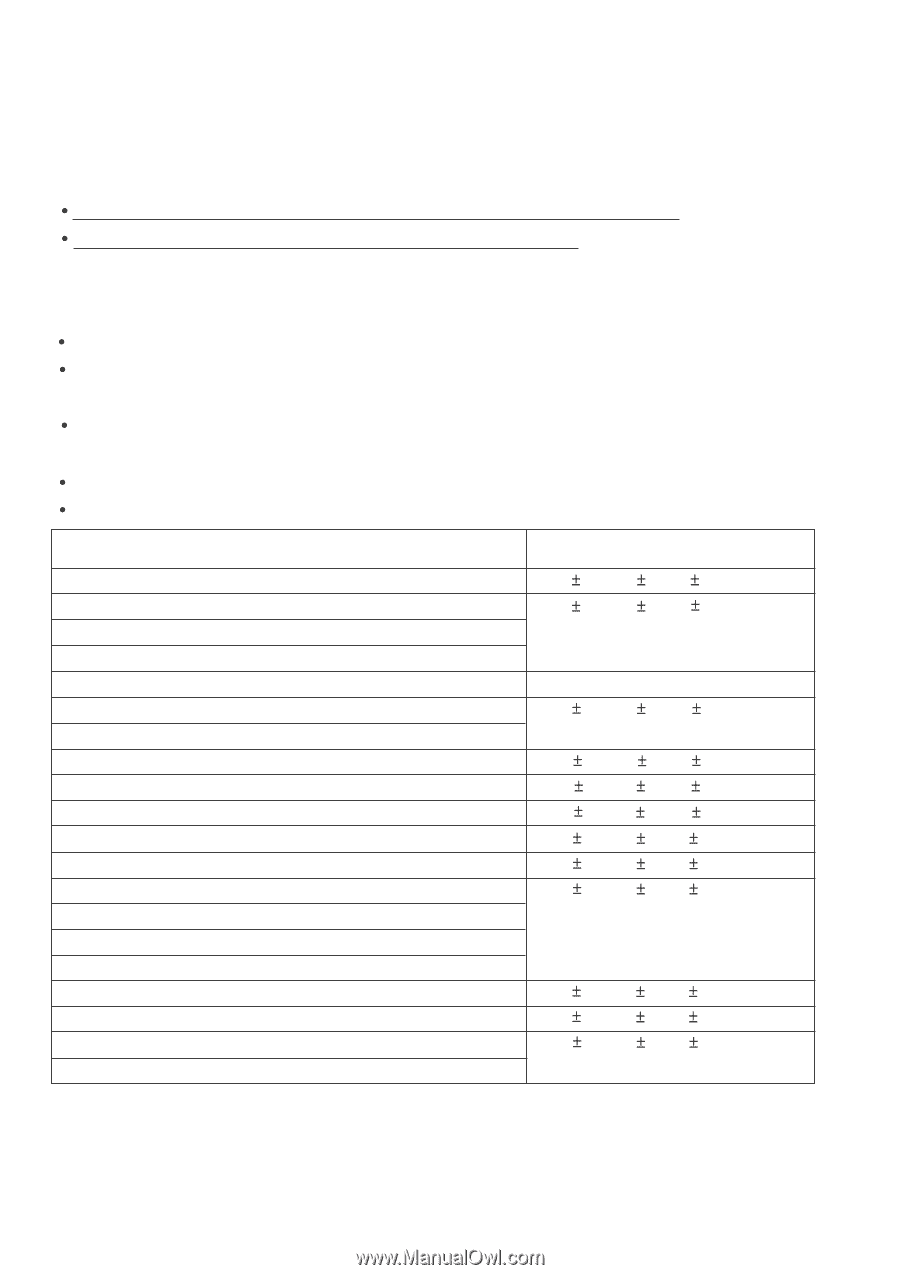

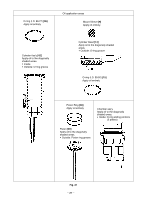

10. DISASSEMBLY AND REASSEMBLY The items particularly necessary for disassembly and reassembly are described below. The [Bold] numbers in the descriptions below correspond to the item numbers in the Parts List and exploded assembly diagram. [CAUTION] Before disassembly or reassembly, be sure to remove all nails, fuel cell and battery. Be sure to tighten the screw of the head securely before driving nails. 10-1. General Precautions in Disassembly and Reassembly Apply grease (ATTOLUB No. 2) (Code No. 317918) to the areas shown in Fig. 22. Apply oil (Gas Nailer Lubricant) (Code No. 885246) (Code No. 885546) to the areas shown in Fig. 21. When installing the O-rings, be careful not to damage the O-rings and prevent dirt entry. Oil required: Hitachi Gas Nailer Lubricant 8 oz. (250 cc) oil feeder (Code No. 885-246) (Code No. 885-546) Use the cleaner (Code No. 885245) for cleaning the inner parts such as O-rings. Tightening torque for each part Bolt and others Hex. Socket Set Screw M4 x 5 31] Hex. Socket Hd. Bolt M4 x 10 61] Hex. Socket Hd. Bolt M4 x 10 43] Hex. Socket Hd. Bolt M4 x 16 21] Hex. Socket Hd. Bolt M4 x 18 127] Hex. Socket Hd. Bolt M5 x 10 66] Hex. Socket Hd. Bolt M5 x 14 1] Hex. Socket Hd. Bolt M5 x 15 76] Hex. Socket Hd. Bolt M5 x 20 13] Hex. Socket Hd. Bolt M5 x 50 51] Seal Lock Hex. Socket Hd. Bolt M5 x 10 58] Tapping Screw (W/Flange) D4 x 14 (Black 95] Tapping Screw (W/Flange) D4 x 16 (Black 78] Tapping Screw (W/Flange) D4 x 20 (Black 83] Tapping Screw (W/Flange) D5 x 20 (Black 126] Tapping Screw (W/Flange) D4 x 45 80] Flat Hd. Tapping Screw D4 104] Machine Screw M4 x 6 28], [33], [46] Nut M4 18] Spark Plug (A 11] Tightening torque N•m (kgf•cm, ft-lb) 3.4 0.7 (35 7, 2.5 0.5) 4.6 0.5 (45 5, 3.4 0.4) 1.0 to 1.5 (10 to 15, 0.7 to 1.1) 6.4 0.5 (65 5, 4.7 0.4) 5.9 0.5 (60 5, 4.4 0.4) 6.4 0.5 (65 5, 4.7 0.4) 6.9 0.5 (70 5, 5.1 0.4) 8.3 0.5 (85 5, 6.1 0.4) 1.5 0.5 (15 5, 0.7 0.4) 3.0 0.5 (30 5, 2.2 0.4) 1.0 0.3 (10 3, 0.7 0.2) 1.8 0.4 (18 4, 1.3 0.3) 1.0 0.2 (10 2, 0.7 0.1) --- 28 ---