LG LRBP1031W User Guide - Page 14

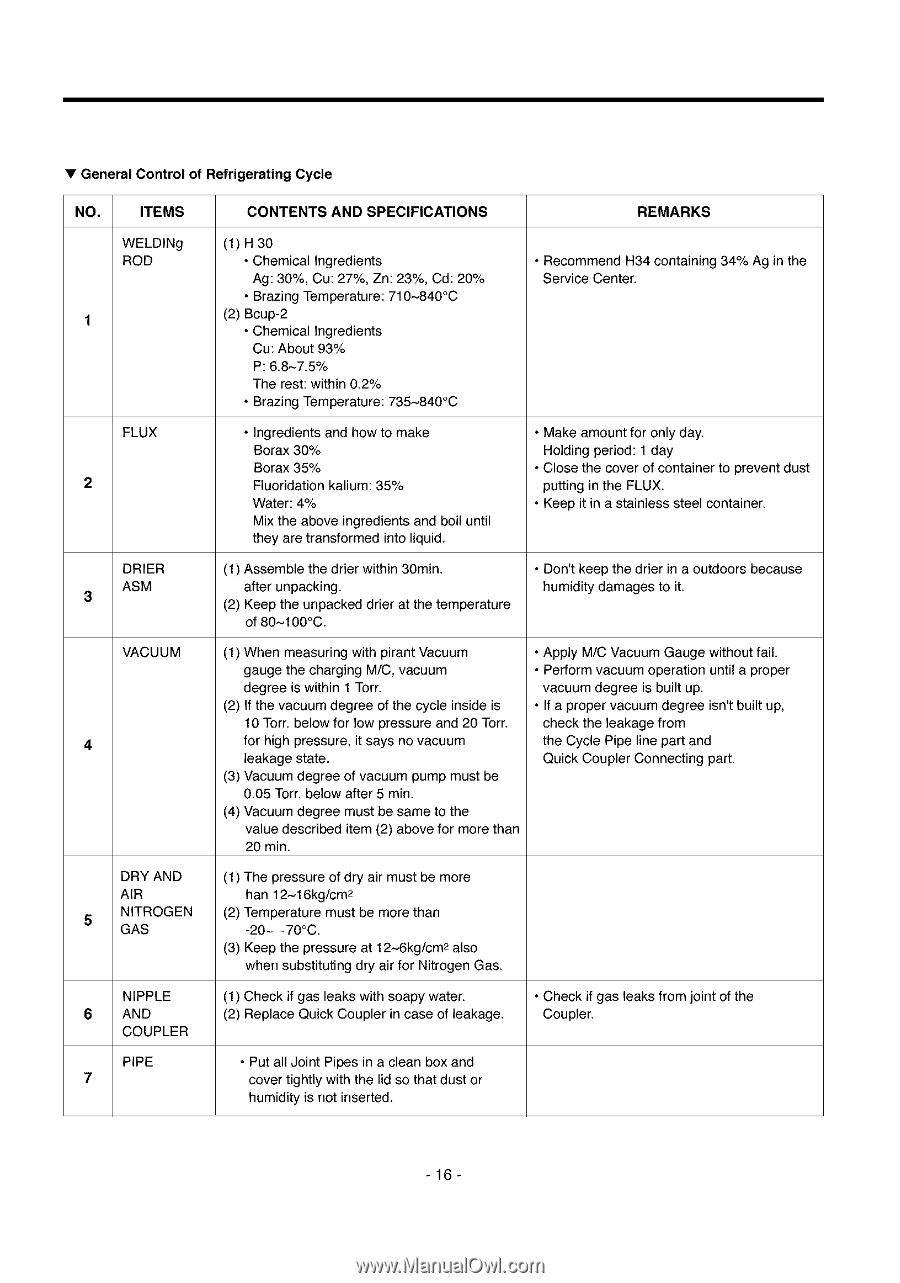

General, Control, of Refrigerating, Cycle, ITEMS, CONTENTS, AND SPECIFICATIONS, REMARKS - stainless steel

|

UPC - 048231777223

View all LG LRBP1031W manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

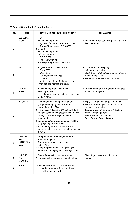

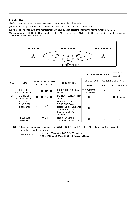

• General Control of Refrigerating Cycle NO. ITEMS WELDINg ROD FLUX DRIER ASM VACUUM DRY AND AIR NITROGEN GAS NIPPLE 6 AND COUPLER PiPE 7 CONTENTS AND SPECIFICATIONS REMARKS (1) H 30 • Chemical Ingredients Ag: 30%, Cu: 27%, Zn: 23%, Cd: 20% • Brazing Temperature: 710~840°C (2) Bcup-2 • Chemical Ingredients Cu: About 93% P: 6.8~7.5% The rest: within 0.2% • Brazing Temperature: 735~840°C • Recommend H34 containing 34% Ag in the Service Center. • Ingredients and how to make Borax 30% Borax 35% Fluoridation kalium: 35% Water: 4% Mix the above ingredients and boil until they are transformed into liquid. • Make amount for only day, Holding period: 1 day • Close the cover of container to prevent dust putting in the FLUX. • Keep it in a stainless steel container. (1) Assemble the drier within 30min. after unpacking. (2) Keep the unpacked drier at the temperature of 80~100°C. • Don't keep the drier in a outdoors because humidity damages to it. (1) When measuring with pirant Vacuum gauge the charging M/C, vacuum degree is within 1 Torr. (2) If the vacuum degree of the cycle inside is 10 Torr. below for low pressure and 20 Torr. for high pressure, it says no vacuum leakage state. (3) Vacuum degree of vacuum pump must be 0.05 Torr. below after 5 min. (4) Vacuum degree must be same to the value described item (2) above for more than 20 min. • Apply M/C Vacuum Gauge without fail. • Perform vacuum operation until a proper vacuum degree is built up. • If a proper vacuum degree isn't built up, check the leakage from the Cycle Pipe line part and Quick Coupler Connecting part. (1) The pressure of dry air must be more han 12~16kg/cm 2 (2) Temperature must be more than -20- -70°C. (3) Keep the pressure at 12~6kg/cm2 also when substituting dry air for Nitrogen Gas. (1) Check if gas leaks with soapy water. (2) Replace Quick Coupler in case of leakage. • Check if gas leaks from joint of the Coupler. • Put all Joint Pipes in a clean box and cover tightly with the lid so that dust or humidity is not inserted. -16-