Lexmark E260 Service Manual - Page 64

-220, Error, Description, Action, Printhead service - e260d driver

|

View all Lexmark E260 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 64 highlights

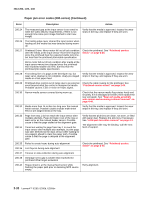

4513-200, -220, -230 Paper jam error codes (200-series) (Continued) Error Description Action 200.24 The measured gap at the input sensor is too small to meet the video delivery requirements. (There is not enough time since prior image finished to start new image) Verify that the media is approved. Inspect the wear strips in the tray, and replace if they are worn. 200.26 The trailing edge never cleared the input sensor when feeding out the media that was detected during warmup. 200.27 Printhead Driver: Mirror motor fell out of lock condition after the media at the input sensor-more time elapsed since the printhead than the expected stable lock time, but less than the printhead jitter-stable specification. Check the printhead. See "Printhead service check" on page 2-65. Mirror motor fell out of lock condition after media at the input sensor-more time elapsed since the printhead than expected stable lock time, but less than the printhead jitter-stable specification. 200.28 First writing line of a page at the developer nip, but Verify that the media is approved. Inspect the wear laser servo cleanup is not complete. Likely pre staged strips in the tray, and replace if they are worn. media or a fast paper feed. 200.29 Printhead drive control out of range due to an external Check the cable routing for the printhead. See event beyond what the control is designed to handle. "Printhead service check" on page 2-65. Probable causes: ESD or noise on hsync signal. 200.30 Narrow media sensor covered during warm-up. Check that the narrow media flag rotates freely and securely. If it is dislodged or broken, then repalce the rear exit guide. See "Rear exit guide assembly with sensor and reversing solenoid removal" on page 4-48. 200.32 Media more than 14 inches too long over the manual feeder sensor. Possible causes include multi-sheet feed or pre-staged media in the tray. Verify that the media is approved. Inspect the wear strips in the tray, and replace if they are worn. 200.33 200.34 Page from tray 1 did not reach the input sensor after multiple attempts. Page did make it out of the tray at least as far as the manual feeder sensor. Possible cause is that the page stalled at the alignment gate. Timed out waiting for page from tray 1 to reach the input sensor after multiple pick attempts, but the page was later detected at the input sensor while waiting for any page(s) ahead to clear the paper path. Possible cause is that the page is delayed at the alignment gate. Verify that the pick tires are clean, not worn, or filled with paper dust. Replace the pick tires if necessary. See "ACM pick tire roller removal" on page 4-3. The alignment roller may be binding. Call the next level of support. 200.35 Failed to create hsync during auto alignment 200.36 Lost hsyncs during auto alignment Check the printhead. See "Printhead service check" on page 2-65. 200.37 Timeout on data collection during auto alignment 200.38 Interpage servo gap is smaller than expected for printhead offset target evaluation 200.42 Rogue sheet is at the manual feed sensor while flushing the paper path prior to declaring MPF source empty. Retry alignment. 2-38 Lexmark™ E260, E260d, E260dn