Ryobi RYI2200 User Manual 3 - Page 17

Checking/adding Lubricant, Using Fuel Stabilizer, Oxygenated Fuels, Checking/adding Fuel, Warning, - inverter generator

|

View all Ryobi RYI2200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

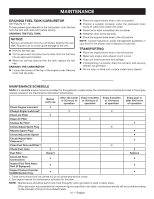

OPERATION CHECKING/ADDING LUBRICANT See Figure 3. NOTICE: Attempting to start the engine before it has been properly filled with lubricant will result in equipment failure. Ethanol. Gasoline containing up to 10% ethanol by volume (commonly referred to as E10) is acceptable. E15 and E85 are not. CHECKING/ADDING FUEL See Figure 4. Engine lubricant has a major influence on engine performance and service life. For general, all-temperature use, SAE 10W-30 is recommended. Always use a 4-stroke motor lubricant that meets or exceeds the requirements for API service classification SJ. NOTE: Non-detergent or 2-stroke engine lubricants will damage the engine and should not be used. n Loosen the screws at the side of the engine cover. Remove cover and set aside. n Unscrew the oil cap/dipstick and remove. n Wipe dipstick clean and re-seat in hole; do not re-thread. n Remove dipstick again and check lubricant level. Lubricant level should fall between the minimum and maximum marks on the dipstick. n If level is low, add engine lubricant until the fluid level rises between the minimum and maximum marks on the dipstick. n Replace and secure the oil cap/dipstick. WARNING: Gasoline and its vapors are highly flammable and explosive. To prevent serious personal injury and property damage, handle gasoline with care. Keep away from ignition sources, handle outdoors only, do not smoke while adding fuel, and wipe up spills immediately. When adding gas to the generator, make sure the unit is sitting on a flat, level surface. If the engine is hot, let the generator cool before adding gas. ALWAYS fill the fuel tank outdoors with the machine turned off. n Remove the fuel cap slowly. n Fill the fuel tank to 1 in. below the top of the fuel neck. n Replace and secure the fuel cap. NOTE: Always use unleaded gasoline with a pump octane rating of 86 or higher. Never use old, stale, or contaminated gasoline, and do not use an oil/gas mixture. Do not allow dirt or water into the fuel tank. Do not use E85 fuel. USING FUEL STABILIZER Fuel gets old, oxidizes, and breaks down over time. Adding a fuel stabilizer (not included) extends the usable life of fuel and helps prevent deposits from forming that can clog the fuel system. Follow fuel stabilizer manufacturer's directions for correct ratio of stabilizer to fuel. STARTING THE ENGINE See Figures 5 - 7. NOTICE: On a level surface with the engine off, check the lubricant level before each use of the generator. Mix fuel stabilizer and gasoline prior to filling the tank by using a gas can or other approved fuel container and shaking gently to combine. NOTE: To control the amount of fuel stabilizer being added to the engine, always mix fuel stabilizer with gasoline before fueling the tank rather than adding fuel stabilizer directly into the generator's fuel tank. n Replace and secure the fuel tank cap. n Start and run the engine for at least 5 minutes to allow stabilizer to treat the entire fuel system. OXYGENATED FUELS NOTICE: Do not use E15 or E85 fuel (or fuel containing greater than 10% ethanol) in this product. It is a violation of federal law and will damage the unit and void your warranty. NOTE: If location of generator is not level, the unit may not start or may shut down during operation. To start generator the first time: Your new inverter generator is equipped with a mechanical fuel pump. The initial start up will require additional pulls of the recoil starter to prime the fuel system. n Turn the ENGINE/CHOKE LEVER to the CHOKE position. n Fill the fuel tank per the Operator's Manual instructions. n Pull the engine recoil five (5) times to prime the fuel system. n Press the AUTO IDLE SWITCH to the OFF position. n Add engine lubricant per the Operator's Manual instruc- tions. n Pull the recoil starter until the engine starts. n Move the CHOKE LEVER to the RUN position. n For quieter more efficient operation, place the AUTO IDLE switch in the ON position. Fuel system damage or performance problems resulting from the use of an oxygenated fuel containing more than the percentage of oxygenates stated below are not covered under warranty. To start subsequent times: NOTE: Subsequent starting should only require 6 pulls maximum. 13 - English