Ryobi RYI2200 User Manual 3 - Page 19

Maintenance - oil change

|

View all Ryobi RYI2200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

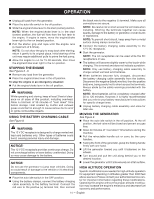

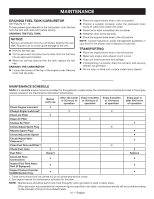

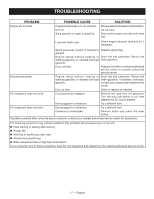

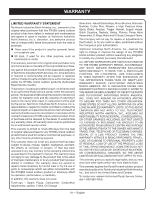

MAINTENANCE WARNING: When servicing, use only identical replacement parts. Use of any other parts could create a hazard or cause product damage. WARNING: Before inspecting, cleaning or servicing the machine, shut off engine, wait for all moving parts to stop, and disconnect spark plug wire and move it away from spark plug. Failure to follow these instructions can result in serious personal injury or property damage. NOTICE: The spark arrestor on this product has not been evaluated by the USDA Forest Service and cannot be used on U.S. forest lands. In addition, product users must comply with Federal, State, and local fire prevention regulations. Check with appropriate authorities. Contact customer service to purchase a replacement spark arrestor. GENERAL MAINTENANCE Keep the generator in a clean and dry environment where it is not exposed to dust, dirt, moisture, or corrosive vapors. Do not allow the cooling air slots in the generator to become clogged with foreign material such as leaves, etc. Do not use a garden hose to clean the generator. Water entering the fuel system or other internal parts of the unit can cause problems that will decrease the life of the generator. To clean the unit: n Use a soft bristle brush and/or vacuum cleaner to loosen and remove dirt and debris. n Clean air vents with low pressure air that does not exceed 25 psi. n Wipe the exterior surfaces of the generator with a damp cloth. CHECKING/CLEANING AIR FILTER See Figures 10 - 11. For proper performance and long life, keep air filter clean. n Loosen the screws on the side of the engine cover. Remove cover and set aside. n Loosen the screw in the center of the air filter cover and turn the cover 1/4 turn clockwise, pulling the cover down and off the unit. Remove air filter cover and set aside. n Remove both the large and the small air filters. n Wash the air filters with warm, soapy water. Rinse and squeeze to dry. n Reinstall the air filters. NOTE: Make sure the filters are seated properly inside the generator. Installing the filters incorrectly will allow dirt to enter the engine, causing rapid engine wear. n Reinstall the air filter cover. Tighten screw to secure. n Reinstall the engine cover. Tighten screws to secure. CHANGING ENGINE LUBRICANT See Figure 12. For best performance, engine lubricant should be changed after every 100 hours or 6 months of operation. n Loosen the screw at the top of the engine cover. Remove cover and set aside. n Remove the oil fill cap/dipstick. n Tilt the generator to the side and allow lubricant to drain from the oil fill hole into an approved container. NOTE: Drain the lubricant while the engine is still warm but not hot. Warm lubricant will drain quickly and more completely. WARNING: Do not change engine lubricant while it is hot. Accidental contact with hot engine lubricant could result in serious burns. n Return the generator to an upright position and refill with lubricant following the instructions in the Checking/Adding Lubricant section previously in this manual. For amount of lubricant needed to refill, see Product Specifications earlier in this manual or the accompanying engine manual, if applicable. n Replace and secure the oil cap/dipstick. Reinstall the engine cover. Replace the screw and tighten securely. NOTE: Used lubricant should be disposed of at an approved disposal site. See your local retailer for more information. SPARK PLUG REPLACEMENT See Figure 13. The spark plug must be properly gapped and free of deposits in order to ensure proper engine operation. To check: n Remove the spark plug cover. n Remove the spark plug cap. n Clean any dirt from around base of spark plug. n Remove spark plug using spark plug wrench. n Inspect spark plug for damage, and clean with a wire brush before reinstalling. If insulator is cracked or chipped, spark plug should be replaced. For replacement spark plug, see Product Specifications earlier in this manual or the accompanying engine manual, if applicable. n Measure plug gap. The correct gap is 0.024−0.028 in. (0.60-0.70 mm). To widen gap, if necessary, carefully bend the ground (top) electrode. To lessen gap, gently tap ground electrode on a hard surface. n Seat spark plug in position; thread in by hand to prevent crossthreading. n Tighten with wrench to compress washer. If spark plug is new, use 1/2 turn to compress washer appropriate amount. If reusing old spark plug, use 1/8 to 1/4 turn for proper washer compression. NOTE: An improperly tightened spark plug will become very hot and could damage the engine. NOTICE: Be careful not to cross-thread the spark plug. Cross-threading will seriously damage the product. 15 - English