Stihl MS 311 Product Instruction Manual - Page 37

Oil Quantity Control, Taking Care of the Guide - 20 bar

|

View all Stihl MS 311 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 37 highlights

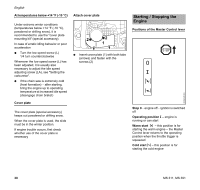

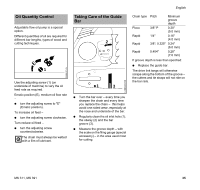

English Oil Quantity Control Adjustable flow oil pump is a special option. Different quantities of oil are required for different bar lengths, types of wood and cutting techniques. 1 Use the adjusting screw (1) (on underside of machine) to vary the oil feed rate as required. Ematic position (E), medium oil flow rate - N turn the adjusting screw to "E" (Ematic position). To increase oil feed - N turn the adjusting screw clockwise. Turn reduce oil feed - N turn the adjusting screw counterclockwise. The chain must always be wetted with a film of lubricant. 001BA157 KN 143BA026 KN Taking Care of the Guide Bar 2 1 3 N Turn the bar over - every time you sharpen the chain and every time you replace the chain - this helps avoid one-sided wear, especially at the nose and underside of the bar. N Regularly clean the oil inlet hole (1), the oilway (2) and the bar groove (3). N Measure the groove depth - with the scale on the filing gauge (special accessory) - in the area used most for cutting. Chain type Picco Rapid Rapid Rapid Pitch Minimum groove depth 3/8" P 0.20" (5.0 mm) 1/4" 0.16" (4.0 mm) 3/8"; 0.325" 0.24" (6.0 mm) 0.404" 0.28" (7.0 mm) If groove depth is less than specified: N Replace the guide bar. The drive link tangs will otherwise scrape along the bottom of the groove - the cutters and tie straps will not ride on the bar rails. MS 311, MS 391 35