Weider Pro 9510 English Manual - Page 5

Assembly - parts

|

View all Weider Pro 9510 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

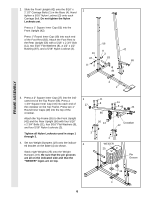

ASSEMBLY Before beginning assembly, carefully read the following information and instructions: • Place all parts of the WEIDER 9510 in a cleared area and remove the packing materials; do not dispose of the packing materials until assembly is completed. • The assembly is divided into five stages: 1) frame assembly, 2) press and butterfly arm assembly, 3) cable and pulley assembly, 4) seat and backrest assembly, and 5) VKR assembly. The hardware for each stage is packaged separately. • Wait until you begin each assembly stage to open that parts bag. • For help identifying the small parts used in assembly, use the PART IDENTIFICATION CHART located in the center of this manual. Note: Some small parts may have been preattached for shipping. If a part is not in the parts bag, check to see if it has been pre-attached. • As you assemble the WEIDER 9510, be sure that all parts are oriented as shown in the drawings. • Tighten all parts as you assemble them, unless instructed to do otherwise. THE FOLLOWING TOOLS (NOT INCLUDED) ARE REQUIRED FOR ASSEMBLY: • Two (2) adjustable wrenches • One (1) standard screwdriver • One (1) phillips screwdriver • One (1) rubber mallet • Lubricant, such as grease or petroleum jelly, and soapy water will also be needed. Assembly will be more convenient if you have the following tools: A socket set, a set of open-end or closed-end wrenches, or a set of ratchet wrenches. FRAME ASSEMBLY 1. Before beginning assembly, be sure that 1 you have read and understand the infor- mation in the box above. Press a 2" Square Outer Cap (51) onto each end of the Stabilizer (5). Press a 2" Square Inner Cap (27) into the end of the Base (4). High Side of Bracket Insert two 5/16" x 2 3/4" Carriage Bolts (14) up through the Stabilizer (5). Insert a 5/16" x 2 1/2" Carriage Bolt (1) up through the Stabilizer. Insert two 5/16" x 2 1/2" Carriage Bolts (1) up through the Base (4). 56 Slotted Hole Slide the indicated end of the Base (4) onto the 5/16" x 2 3/4" Carriage Bolts (14) in the Stabilizer (5). Slide the Rear Upright (56) onto the Carriage Bolts. The high side of the bracket on the Rear Upright must be 8 11 3 3 88 3 on the side shown. Hand tighten a 5/16" Nylon Locknut (3) onto each Carriage Bolt. Do not tighten the Nylon Locknuts yet. 5 51 1 Slide the end of the Brace (88) with the round hole onto the 5/16" x 2 1/2" Carriage 4 Bolt (1) in the Stabilizer (5). Hand tighten a 5/16" Nylon Locknut (3) onto the Carriage 51 14 Bolt. Attach the end of the Brace with the slotted hole to the Rear Upright (56) with a 5/16" x 2 3/4" Bolt (11), a 5/16" Flat Washer (8), and a 5/16" Nylon Locknut (3). Do not 1 27 tighten the Nylon Locknuts yet. 5