2009 Ford E150 Cargo Diesel Supplement 2nd Printing - Page 52

2009 Ford E150 Cargo Manual

Page 52 highlights

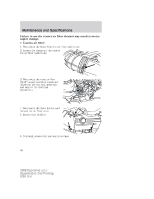

Maintenance and Specifications Passive regeneration In passive regeneration, the exhaust constituents / temperature are at an appropriate level where some soot can be reduced or oxidized (burned) thus cleaning the filter. This method occurs naturally as a result of normal engine operating conditions (at varying levels due to drive patterns). Active regeneration If there is not enough passive regeneration naturally occurring due to vehicle drive patterns, the engine control system will initiate an active regeneration. In an active regeneration, the filter is cleaned by raising the exhaust temperature to a point where the soot is burned away. This is accomplished through various engine actions which raise the exhaust temperature in the oxidation catalyst/DPF system to an appropriate high level where the soot is burned off. After the soot is burned off, the exhaust temperature and back-pressure (restriction) fall back to normal levels. Filter service/maintenance Over time a slight amount of ash will build up in the DPF which is not removed during the regeneration process. The DPF may need to be removed for ash cleaning at approximately 120,000 miles (193,000 km) or greater (actual mileage can vary greatly depending upon engine/vehicle operating conditions) and replaced with a new or remanufactured (ash cleaned) part. The filter may need to be replaced at approximately 250,000 miles (400,000 km) depending upon engine/vehicle operating conditions. In both cases the engine control system will set a service light ( ) to inform you to bring the vehicle to the dealer for service. If there are any issues with the oxidation catalyst/DPF system a service or ) will be set by the engine control system to inform light ( you to bring the vehicle into a dealership for service. Resonator/Tailpipe assembly maintenance The diesel resonator tail-pipe assembly is a uniquely functioning device that accompanies the Oxidation Catalyst/DPF assembly. The assembly serves multiple functions. First it serves as an acoustic device to attenuate exhaust noise. Second it provides an exit path for the exhaust from the vehicle. It also is designed to help control the temperature of the exhaust during DPF regeneration events. The visible holes in each leg of the twin tip and the holes under the shield just inboard of the 52 2009 Econoline (eco) Supplement, 2nd Printing USA (fus)