Bosch WTMC6321US User Guide - Page 7

Exhaust, air connection

|

View all Bosch WTMC6321US manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

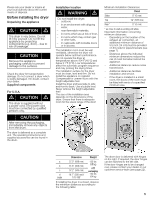

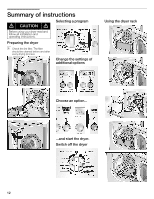

2. Make sure that there is a grounding strap. 3. Fix the strain relief clamp to the angle bracket. Tighten the nut. 4. Loosen the 2 screws labeled L and the screw labeled N in the terminal block. 5. Thread the 3Ćwire cable through the U.L. strain relief clamp. 6. Tighten the screws (2.5 Nm) on the U.L. strain relief clamp so that the power cord cannot be moved. 7. Attach the 2 power cord outer conductors (red and black) to the 2 terminals labeled L and the remaining power cord conductor (white) to the terminal labeled N. 8. Tighten all 3 screws (3 Nm) so that the power conductors are held in place securely. 9. Check the U.L. strain relief clamp to make sure that it is tight and cannot be turned. 10. Replace the cover on the terminal block and fasten in place. i Make sure that the U.L. strain relief clamp is outside the cover! Additional grounding procedure - Some local regulations may require a separate ground. In such cases, the required accessory ground wire, clamp and screw must be purchased separately. - Never ground the dryer to plastic plumbing lines, gas lines or water pipes. Grounding instruction This appliance must be grounded. In the event of a malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for the electric current. For Canada the dryer comes with a cord which has an equipment grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet which has been properly installed and grounded in accordance with all local regulations and ordinances. d WARNING d Improper connection of the equipment grounding conductor may result in electric shock. Have the appliance checked by a qualified electrician or service technician if you are in doubt as to whether the dryer has been properly grounded. Exhaust air connection d WARNING d 1. To reduce the risk of fire, this dryer MUST BE EXHAUSTED OUTDOORS. 2. To reduce the risk of fire, do not use the ductwork longer than recommended. 3. DO NOT use a plastic or nonĆmetal duct with this dryer. 4. DO NOT use a duct smaller than 4 inches in diameter. 5. DO NOT use exhaust hoods with magnetic latches. 6. DO NOT exhaust the dryer into a chimney, furnace cold air duct, attic, crawl space, or any other ductwork used for venting. 7. DO NOT install a flexible duct in an enclosed wall, ceiling or floor. 8. DO NOT crush or kink the duct. 9. Do clean and inspect the exhaust system on a regular basis; at least once a year. 10. The exhaust duct must terminate in a manner to prevent back drafts or entry of birds or other wildlife. The Bosch dryers are intended to be vented outdoors. To prevent buildĆup of moisture and accumulation of lint indoors, as well as to maintain maximum drying efficiency, it is recommended that the dryer is vented outdoors. Exhaust air outlet on the dryer The dryer is delivered with an exhaust air outlet on the rear of the appliance. To take account of the spatial requirements and an existing exhaust air system, the following connection options are possible for the exhaust air outlet: - on right side of the appliance, - on the underside of the appliance. 2 1 3 1 ć Exhaust air outlet on the rear of the appliance (standard) 2 ć Exhaust air outlet on the side (optional) 3 ć Exhaust air outlet on the underside of the appliance (optional) Special exhaust air connections must be obtained from your dealer or part supplier for either connection type (see page 8). - Side exhaust kit - Bottom exhaust kit A qualified technician should change the exhaust air outlet to the optional connection location. Ductwork To ensure optimum performance, the ducting system of the dryer should be as short as possible with a minimum number of elbows. Your dryer will work best when the venting system has as few air flow restrictions as possible. Exhaust ducting which is longer than recommended may extend drying time, cause lint to accumulate and affect dryer performance and dryer lifeĆtime. FourĆinch (approx. 100 mm) diameter ducting should be used. Use either rigid metal or flexible metal ducting material. DO NOT use plastic or nonĆmetal duct with this dryer. DO NOT assemble the ductwork with screws or fasteners that extend into the duct. They will serve as an accumulation point for lint. Joints should be secured with aluminum tape. 7