Brother International 4234DT Users Manual - English and Spanish - Page 11

Differential feed, Adjusting the presser foot pressure - serger

|

View all Brother International 4234DT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

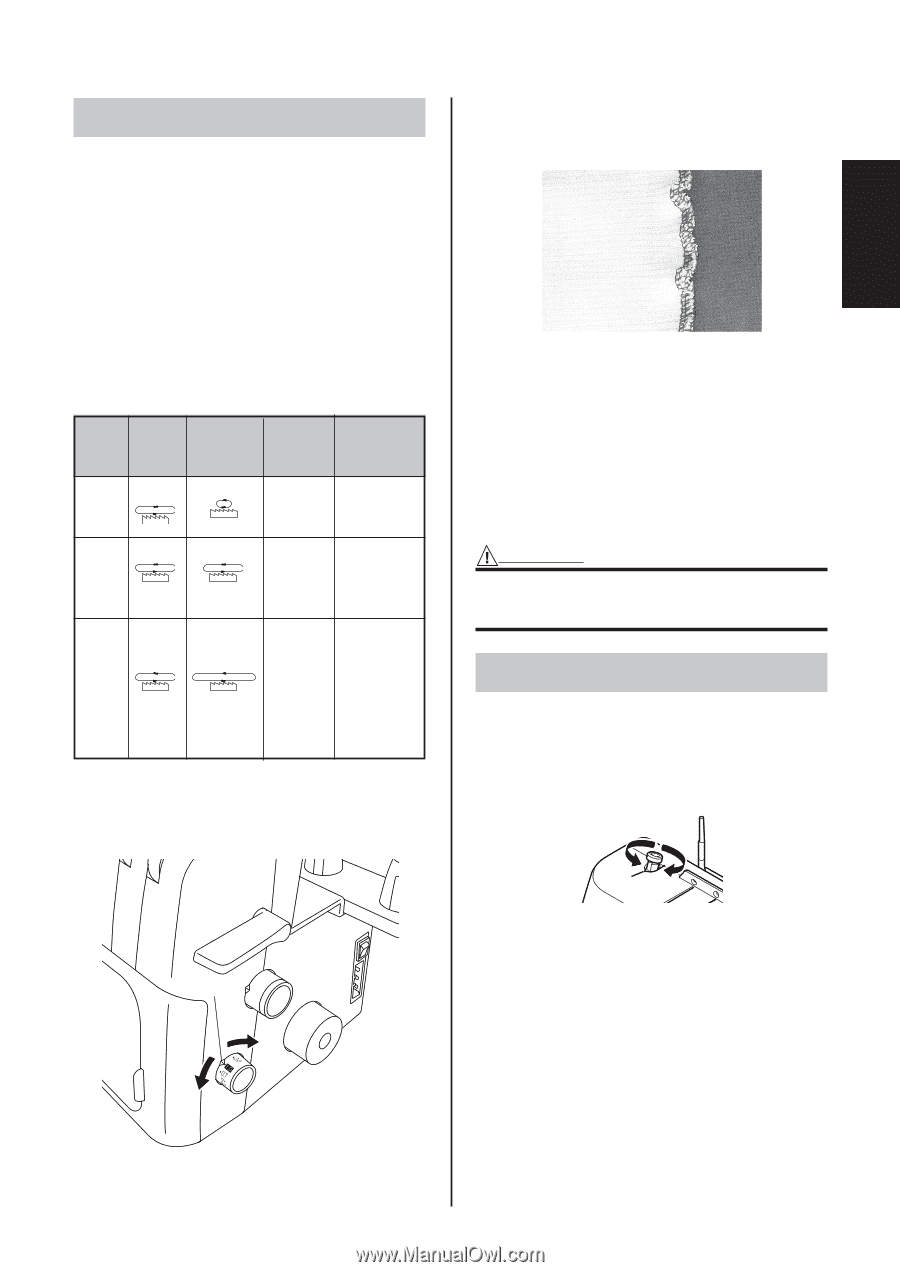

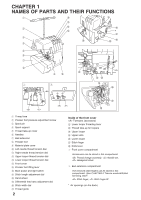

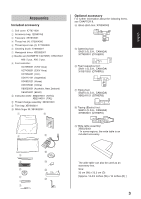

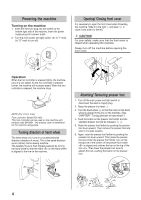

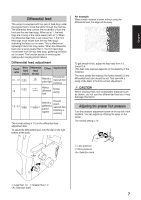

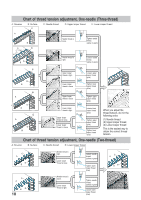

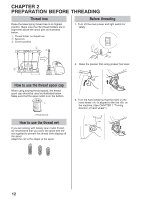

English Differential feed This serger is equipped with two sets of feed dogs under the presser foot to move the fabric through the machine. The differential feed controls the movement of both the front and the rear feed dogs. When set at 1, the feed dogs are moving at the same speed (ratio of 1). When the differential feed ratio is set at less than 1, the front feed dogs move slower than the rear feed dogs, stretching the fabric as it is sewn. This is effective on lightweight fabric that may pucker. When the differential feed ratio is set at greater than 1, the front feed dogs move faster than the rear feed dogs, gathering the fabric as it is sewn. This function assists in removing the rippling when serging stretch fabrics. Differential feed adjustment Feed ratio 0.7 - 1.0 Main Differential Effect Application feed feed (rear) (front) Material is pulled tight. Prevents thin materials from puckering 1.0 Without differential feed. Normal sewing 1.0 - 2.0 Material is gathered or pushed together. Prevents stretch materials from stretching or puckering The normal setting is 1.0 on the differential feed adjustment dial. To adjust the diffrerential feed, turn the dial on the right bottom of the body. 1 2 An example When stretch material is sewn without using the differential feed, the edge will be wavy. To get smooth finish, adjust the feed ratio from 1.0 toward 2.0. (The feed ratio required depends on the elasticity of the material.) The more elastic the material, the further toward 2.0 the differential feed ratio should be set. Test sew with a scrap of the fabric to find the correct adjustment. CAUTION When sewing thick non-stretchable material such as denim, do not use the differential feed as it may damage the fabric. Adjusting the presser foot pressure Turn the pressure adjustment screw on the top left of the machine. You can adjust by reffering the value on the screw. The normal setting is "2". 1 2 1 Less pressure 2 More pressure Selection mark 1 Less than 1.0 2 Greater than 1.0 Selection mark 7