Craftsman 30084N Operation Manual - Page 25

Holding And Positioning Welding Gun

|

UPC - 055249070420

View all Craftsman 30084N manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

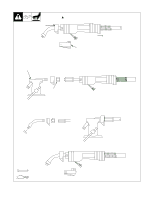

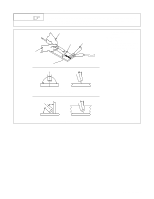

6-3. Holding And Positioning Welding Gun NOTE Welding wire is energized when gun trigger is pressed. Before lowering helmet and pressing trigger, be sure wire is no more than 1/2 in (13 mm) past end of nozzle, and tip of wire is positioned correctly on seam. 1 3 2 5 1 Hold Gun and Control Gun Trigger 2 Workpiece 3 Work Clamp 4 Electrode Extension (Stickout) 1/4 to 1/2 in (6 To 13 mm) 5 Cradle Gun and Rest Hand on Workpiece 4 90° 90° 0°-15° End View Of Work Angle Side View Of Gun Angle GROOVE WELDS 45° 45° 0°-15° End View Of Work Angle Side View Of Gun Angle FILLET WELDS S-0421-A OM-194 199 Page 22

OM-194 199 Page 22

6-3.

Holding And Positioning Welding Gun

Welding wire is energized when gun trigger is pressed. Before lowering helmet and

pressing trigger, be sure wire is no more than 1/2 in (13 mm) past end of nozzle,

and tip of wire is positioned correctly on seam.

NOTE

1

Hold Gun and Control Gun

Trigger

2

Workpiece

3

Work Clamp

4

Electrode Extension (Stickout)

1/4 to 1/2 in (6 To 13 mm)

5

Cradle Gun and Rest Hand on

Workpiece

2

3

5

4

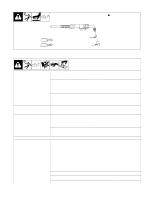

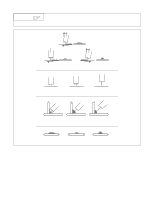

90

°

90

°

0

°

-15

°

45

°

45

°

GROOVE WELDS

FILLET WELDS

End View Of Work Angle

Side View Of Gun Angle

End View Of Work Angle

Side View Of Gun Angle

1

0

°

-15

°

S-0421-A