Craftsman 30084N Operation Manual - Page 31

Common MIG Shielding Gases

|

UPC - 055249070420

View all Craftsman 30084N manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 31 highlights

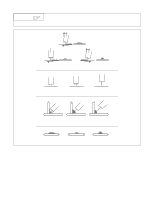

6-16. Common MIG Shielding Gases This is a general chart for common gases and where they are used. Many different combinations (mixtures) of shielding gases have been developed over the years. The most commonly used shielding gases are listed in the following table. Gas Argon Argon + 25% CO2 CO2 Tri-Mix3 Spray Arc Steel Application Short Circuiting Steel Short Circuiting Stainless Steel Flat & Horizontal1 Fillet Flat & Horizontal1 Fillet All Positions All Positions All Positions2 All Positions Short Circuiting Aluminum All Positions 1 Globular Transfer 2 Single Pass Welding Only 3 90% HE + 7-1/2% AR + 2-1/2% CO2 OM-194 199 Page 28

OM-194 199 Page 28

6-16.

Common MIG Shielding Gases

This is a general chart for common gases and where they are used. Many different combinations (mixtures) of

shielding gases have been developed over the years. The most commonly used shielding gases are listed in the

following table.

Application

Gas

Spray Arc Steel

Short Circuiting Steel

Short Circuiting

Stainless Steel

Short Circuiting

Aluminum

Argon

All Positions

Argon + 25% CO

2

Flat & Horizontal

1

Fillet

All Positions

All Positions

2

CO

2

Flat & Horizontal

1

Fillet

All Positions

Tri-Mix

3

All Positions

1

Globular Transfer

2

Single Pass Welding Only

3

90% HE + 7-1/2% AR + 2-1/2% CO

2