HP BL260c ISS Technology Update, Volume 6 Number 7 - Newsletter - Page 12

HP BladeSystem c-Class power structure, Lower cost, Higher reliability/Mean Time Between Failure MTBF - service manual

|

UPC - 883585668663

View all HP BL260c manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

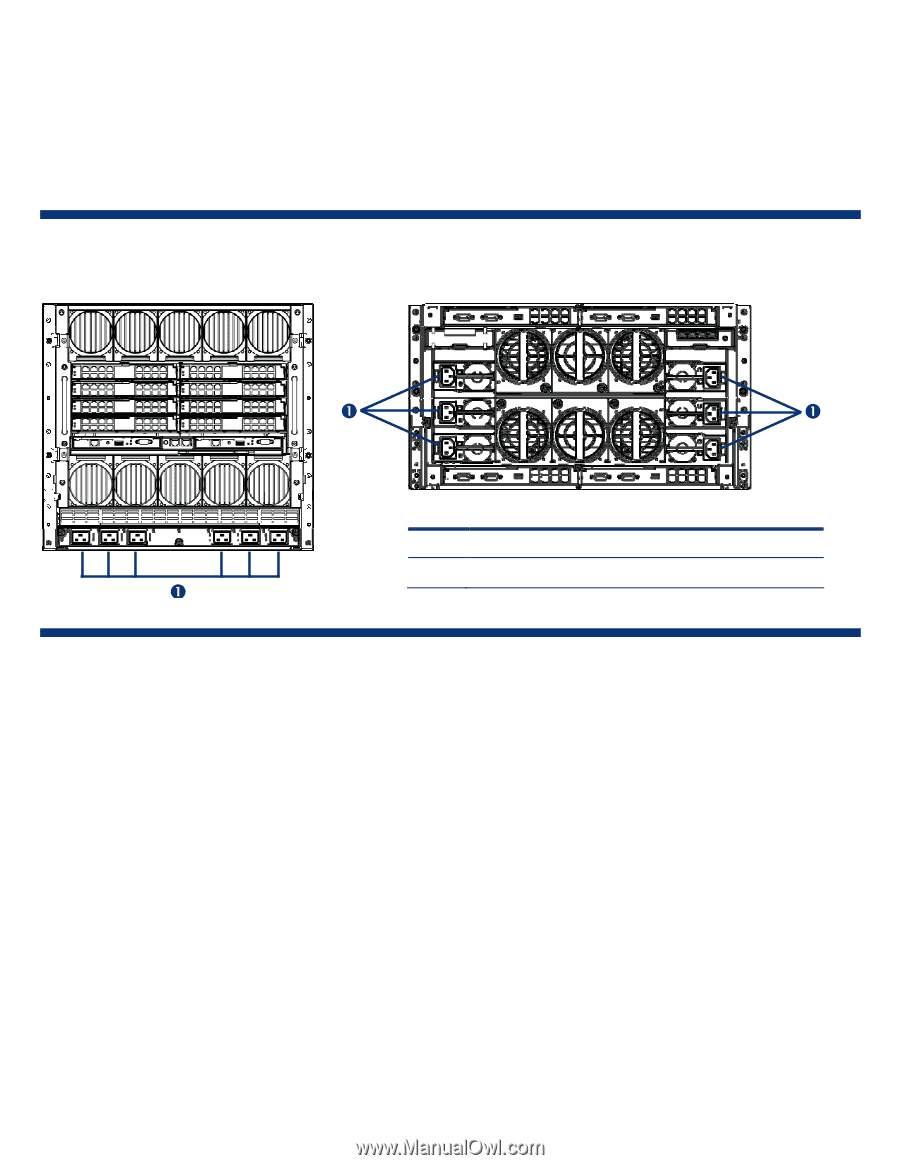

ISS Technology Update Volume 6, Number 7 HP BladeSystem c-Class power structure The BladeSystem c-Class architecture advances to a level where each enclosure is responsible for its own power, independent of other enclosures. No longer do we have physically separate enclosure subsystems (power and server), bus bars, or DC power cables with in-use service complexities (Figure 4-2). Complete power integration negates the previous need for AC and DC breakers at multiple stages of an external power distribution subsystem. Figure 4-2. HP BladeSystem c-Class power connectors HP BladeSystem c7000 enclosure HP BladeSystem c3000 enclosure n n Item Description 1 AC power connectors (6) n Each c7000 and c3000 enclosure connects directly to the customer's AC power infrastructure with industry-standard power cords. The power supply modules installed into each enclosure convert AC power to 12 VDC for distribution inside each respective enclosure. There are no separate power enclosures, external bus bars, or DC power cables to buy, install, or service. Electronic fuse circuits integrated into the c-Class enclosures insure equipment protection and fault isolation should one occur. This provides a high degree of safety and availability. With no physically separate subsystems to connect/disconnect or service, there is no requirement for conventional circuit breakers. HP BladeSystem c-Class's integrated enclosure designs have advantages in several areas: • Lower cost: The integration reduces the cost compared to solutions with multiple external subsystems. The HP BladeSystem c-Class enclosure costs are kept lower by designs that avoid using conventional circuit breakers. No system design, service, or safety considerations mandate the presence of such circuit breakers on c-Class enclosures, so no real advantage would be gained by their addition. • Higher reliability/Mean Time Between Failure (MTBF): An integrated system design without the need for conventional circuit breakers local to the enclosure will have higher reliability and MTBF than that same system with circuit breakers included. This would factor into a lower Total Cost of Ownership over time. • Human error avoidance: Conventional circuit breakers offer the opportunity to manually de-energize the "wrong" breaker, prompting an unintentional major loss of service. Enclosure designs with no requirement for conventional circuit breakers lessen the opportunity for unintentional outages. Incorporating an unnecessary local circuit breaker on the c-Class enclosure could potentially cause a dangerous safety misunderstanding or oversight. A circuit breaker can only de-energize power downstream of the breaker itself. A local circuit 12