HP LaserJet Enterprise P3015 HP LaserJet Printer Family - Print Media Specific - Page 18

Summary of HP envelope testing, Good construction

|

View all HP LaserJet Enterprise P3015 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

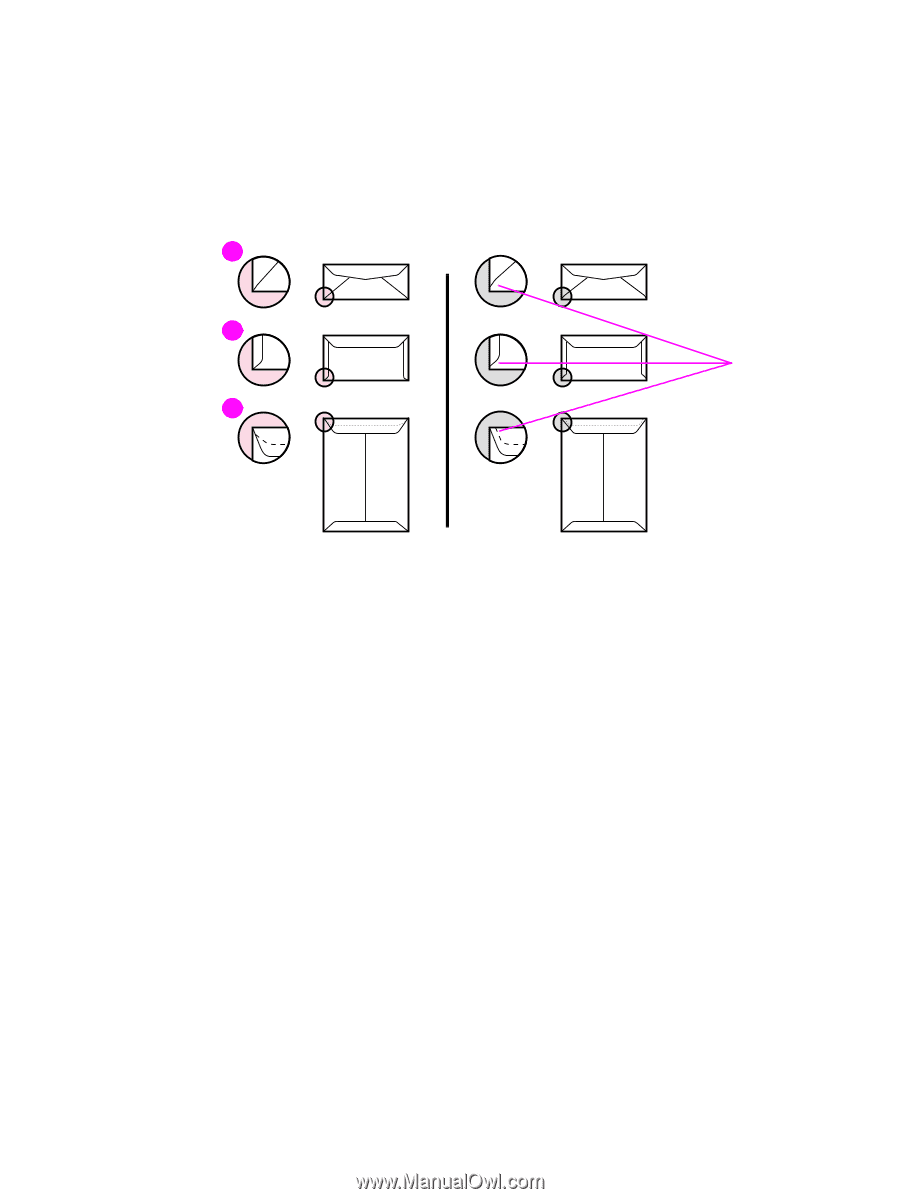

Many envelopes will feed through your HP LaserJet printer without problems. However, some envelope constructions (as shown in the following figure) might not feed reliably. Problems can occur when the envelopes are folded more tightly than normal, which creates a thick leading edge near a corner. Inconsistencies in folding during manufacturing can cause some envelopes to feed well and others to jam. Purchase envelopes that have the quality and consistency that you require. Good construction 1 Bad construction 2 inconsistent leading edge 3 1 Diagonal-seam envelope 2 Double-sided seam envelope 3 Manila envelope Summary of HP envelope testing Hewlett-Packard tests many types of envelopes to determine which ones print acceptably in an HP LaserJet printer. Some of the test results are listed here. q Commercial or Official envelopes (also called Business or Regular), which have diagonal seams and standard gummed flaps, performed the most reliably. q Envelopes that have double-sided seam construction, which creates vertical seams at both ends of the envelope instead of diagonal seams, tend to be more flimsy than diagonal-seam envelopes. Double-sided seam envelopes tend to jam or wrinkle unless the edges are thin and sharply creased. However, a variety of double-sided seam envelopes have performed acceptably during testing. q Envelopes that have a peel-off adhesive strip, or that have more than one flap that folds over for sealing, must use adhesives compatible with the heat and pressure of the printer's fusing process. Many varieties of this type of envelope performed satisfactorily in HP testing; however, the extra flaps and strips can result in increased jamming or wrinkling. q Generally, feeding problems increase with envelope size. Larger envelope sizes (C5, B5) cannot have a basis weight greater than 105 g/m2 (28 lb). q Rougher finishes such as laid, linen, or cockle can result in poor fusing. q The multiple layers in envelopes construction might result in a noticeable background effect (small toner particles scattered in the non-imaged areas). You can reduce this effect by increasing the toner density setting on your printer. 12 Using print media ENWW