HP LaserJet Enterprise P3015 HP LaserJet Printer Family - Print Media Specific - Page 21

Recommendations, the labels peeling and the occurrence of adhesive contamination.

|

View all HP LaserJet Enterprise P3015 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

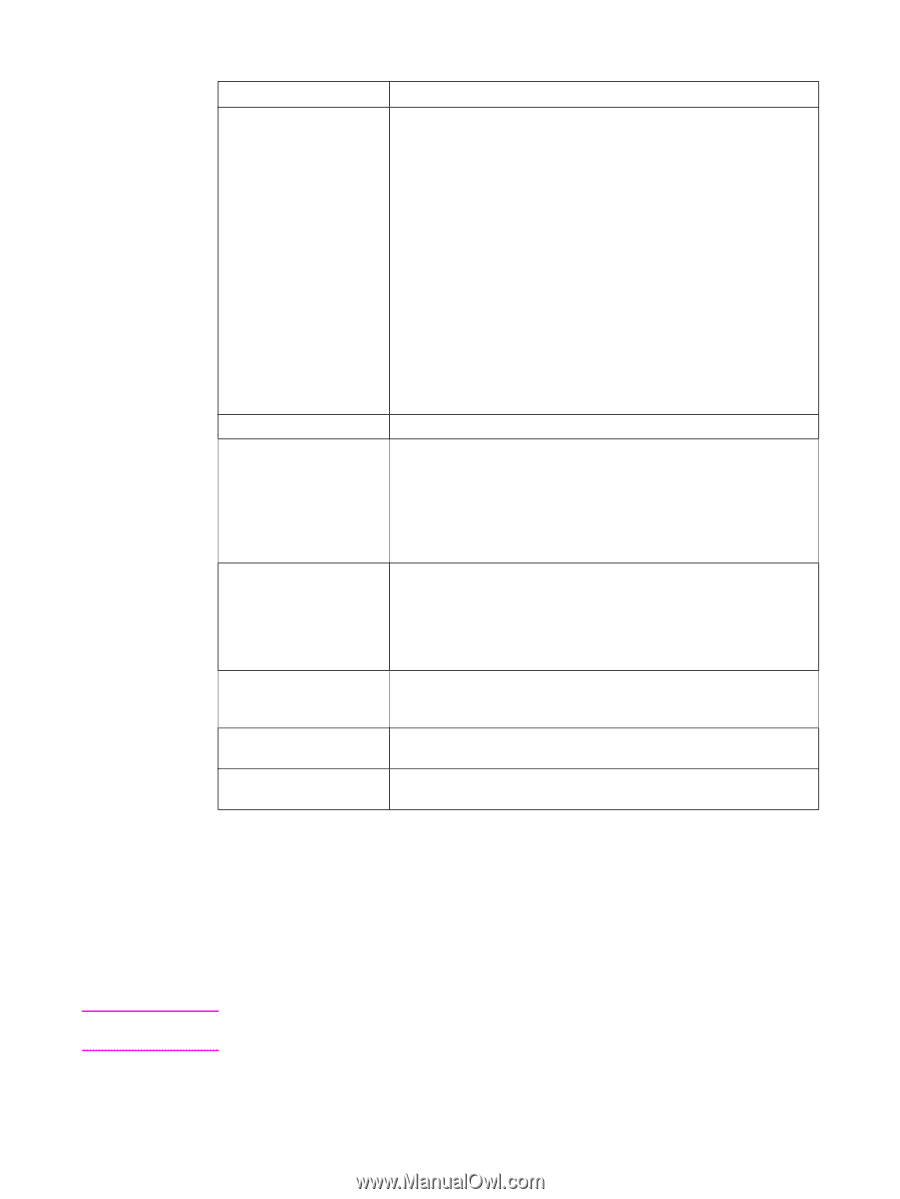

CAUTION Property Adhesives Caliper Face sheet Fusing compatibility Liner Packaging Shelf life Specifications Adhesives must not be on any external surfaces of the label before, during, or after printing. Label construction, adhesive release strength, and appropriate die-cutting must prevent labels from peeling off during printing. Different adhesives can provide removable, permanent, or semi-permanent fixing of the face sheet onto the item being labeled. Generally, acrylic-based adhesives are preferred for laser printing because they can be applied in very thin layers to prevent oozing and contamination, and can be made compatible with the heat and pressure of fusing. Improved processes are being developed to minimize adhesive contamination, such as zone coating or stripped matrix. Zone coating recesses the adhesive around the border of a die-cut, and stripped matrix prevents adhesive from oozing between the die-cut labels. The adhesive and liner must provide adequate release strength so that labels will not peel off during printing. The caliper must not exceed 0.23 mm (9.0 mils). The face sheet is the printable surface on a sheet of adhesive labels and can be made from different materials, including paper, polyester, and vinyl. It is common for a face sheet to be die-cut so that individual shapes can be removed after printing. Polyester and vinyl labels require a topcoat to provide the proper electrical and toner adhesion properties. It is important to purchase labels from a knowledgeable converter who is familiar with these processes and laser printing. All inks, adhesives, and other materials that are used in the label construction must be compatible with the heat and pressure of the fusing process. Materials must not scorch, melt, ignite, offset materials, or release undesirable emissions when heated to 205° C (401° F) for 0.1 second (0.2 second for HP color LaserJet printers). The liner is the carrier sheet for the label material. The liner must provide stability for the reliable pickup and transport of the label stock through the printer. The labels should be delivered in moisture-proof wrap to preserve their properties. The labels should have a minimum shelf life of one year, when stored at 23° C (73° F) and 50 percent relative humidity. Recommendations q Regularly inspect your labels after printing for any indication that the label edges are lifting or that adhesive contamination is occurring on the print surface. If either of these problems is observed, HP recommends that you discontinue use of that box or lot-number of labels and discuss the problem with your label supplier. q If many sheets of labels are being continuously run, periodically run several sheets of paper through the printer to clean any contamination or label-stock adhesive that might have deposited. Make sure to run full sheets of labels. Reprinting unused portions can increase the risk of the labels peeling and the occurrence of adhesive contamination. 2 Guidelines for using media 15