LiftMaster SW470 SW490 S3 BOARD Manual - Page 24

Troubleshooting - gate operator troubleshoot

|

View all LiftMaster SW470 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

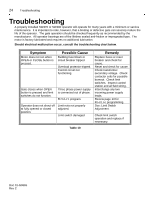

24 Troubleshooting Troubleshooting A properly installed SW470 or SW490 operator will operate for many years with a minimum or service maintenance. It is important to note, however, that a binding or defective gate can severely reduce the life of the operator. The gate operation should be checked frequently as recommended by the manufacturer. All operator bearings are of the lifetime sealed anti-friction or impregnated type. The motor is factory lubricated and requires no additional lubrication. Should electrical malfunction occur, consult the troubleshooting chart below. Symptom Motor does not run when OPEN or CLOSE button is pressed. Gate closes when OPEN button is pressed and limit switches do not function. Operator does not shout off at fully opened or closed position. Possible Cause Building fuse blown or circuit breaker tripped Overload protector tripped. Control circuit not functioning. Three phase power supply is connected out of phase. R.H./L.H. program. Limit nuts not properly adjusted. Limit switch damaged. Remedy Replace fuses or reset breaker and check for cause. Reset and check for cause. Check transformer secondary voltage. Check contactor coils for possible burnout. Check limit switches. Inspect control station and all field wiring. Interchange any two incoming power supply leads. Review page 13 for R.H./L.H. programming. See: Limit Switch Adjustment. Check limit switch operation and replace if necessary. Table 10 Doc 01-G0665 Rev C