Maytag MGC5536BDS Installation Manual - Page 5

Illustrative, Supply, Piping - manual

|

View all Maytag MGC5536BDS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

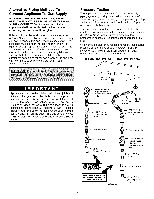

2. IF THIS UNIT WILL HAVE A MAYTAG MODEL MEW6500 or MEW5500 SERIES ELECTRIC WALL OVEN INSTALLED BELOW THIS COOKTOP. NOTE 1 : This appliance and its gas and electrical supply sources must be installed before the wall oven is installed. See illustration (Electrical Wiring Information - page 7; figure 6) for recommended electrical supply source locations. NOTE 2" It may be necessary to extend gas supply piping for this appliance into adjacent under-counter cabinetry when a wall oven is installed below this appliance. Join a 3/8" NPT pipe elbow (locally available) to the male threads at the manifold entrance. When joined, ensure open threads of the elbow face toward the right side of the appliance. Install the appliance in its counter cutout. Join a 3/8" NPT pipe nipple to the elbow using a pipe section of sufficient length to extend, horizontally, beyond the right side of the wall oven. (To accomplish this it may be necessary to extend the pipe section into adjacent cabinetry.) Join additional 3/8" NPT elbow(s) and pipe nipples, as necessary, to accomplish the following: Join the outlet of the appliance pressure regulator supplied with this appliance to the male threads of the newly installed gas supply piping. Install the appliance regulator in a location which will be accessible beside or below the wall oven. Insure the appliance regulator is installed with its directional arrow pointing in the direction of gas flow. Tighten the appliance regulator to 20 to 30 ft-lbs of torque. Never tighten to more than 35 ft-lbs of torque. Always use an approved pipe joint compound resistant to the action of LP gas. Locate and join a manual shut-off valve in an accessible location in the gas line ahead of the appliance regulator and external to the appliance for the purpose of turning on or shutting off gas to the appliance. Make additional pipe connections as necessary ahead of the shut-off valve to the gas supply source. Assure all pipe joint connections are gas tight. Apply a non-corrosive leak detection fluid to all joints and fittings in the gas connection between the supply line shut-off valve and the cooktop. Include gas fittings and joints in the cooktop if connections were disturbed during installation. Check for leaks! Bubbles appearing around fittings and connections will indicate a leak. If a leak appears, turn off supply line gas shut-off valve, tighten connections, turn on the supply line gas shut off valve, and retest for leaks. Never test for gas leaks with an open flame. ILLUSTRATIVE GAS SUPPLY PIPING (WALL OVEN INSTALLED BELOW 30" COOKTOP) _,j. "_'--_ (REAR OF APPLIANCE) i":'iiiiiiiii:_i___:iiiii.'.:iii::::_: ' ' MANIFOLD ,, ii _i::: _=_/-_{--_ELBOW PIPING PASSES THROUGH DIVIDING WALL BE-I'WEEN ADJACENT CAB NETS _"f to suit) APPLIANCE PRESSURE REGULATOR MANUAL SHUTOFF VALVE L INLET ALLUNITSIDE APPROXIMATCEROSSSECTIONALLSUPPLYSIDE PIPEJOINTS PROFILOEFWALLOVEN PIPEJOINTS 3/8"N.RT. 1/2"N.RT. FIGURE4 Note, regarding Figure 4, above: • For convenience in service a union (not shown: locally available) should be included in the piping illustrated in figure 4, in a location most practical for the installation. Generally, a practical location is in the cabinet below this appliance, near the manifold entrance, rather than in an adjoining cabinet. If the alternative piping method shown in figure 5 is selected for the installation, no union is required. (The flexible appliance connector illustrated provides the union joints necessary for servicing.) When a dividing wall is present and a flexible connector is used it is recommended for convenience, in both installation and service, the flexible connector, itself, pass through the dividing wall. Any flexible connector used with this appliance must satisfy all requirements stated in the text accompanying figure 5.