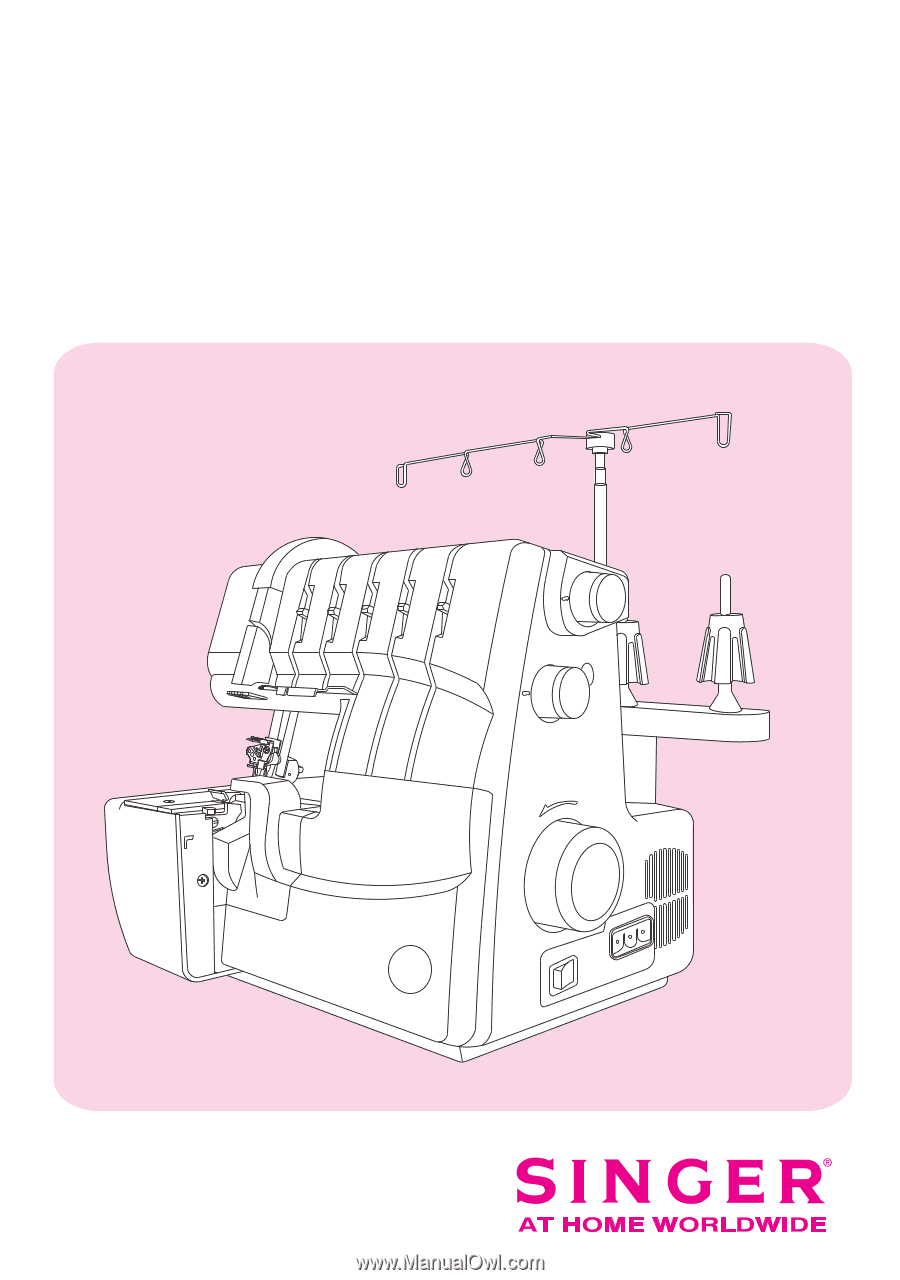

Singer 14T968DC PROFESIONAL 5 Instruction Manual 31

Singer 14T968DC PROFESIONAL 5 Manual

|

View all Singer 14T968DC PROFESIONAL 5 manuals

Add to My Manuals

Save this manual to your list of manuals |

Singer 14T968DC PROFESIONAL 5 manual content summary:

- Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 1

14T968DC Instruction Book - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 2

14T968DC This SINGER sewing machine, model 14T968DC, SINGER is a registered trademark of The Singer Company Limited or its affiliates. ©2008 The Singer Company Limited or its affiliates. All rights reserved. - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 3

area, such as threading needle and loopers, changing needle, changing throat plate or changing presser foot, etc. * Always unplug the machine from the electrical outlet when removing covers, lubricating, or when making any other user servicing adjustments mentioned in the Instruction Book. * Do not - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 4

the Instruction Book. * The appliance is not intended for use by young children or infirm persons without supervision. * Young childen should be supervised to ensure that they do not play with the appliance. * Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord. * SERVICING OF - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 5

Cover 12 8. Preparation prior to sewing 12 9. Removal and Replacement of Waste Tray 13 10. Preparation for Threading 14 *Setting up the thread guide holder 14 *Anti-spill net 14 *Spool cap 14 11. How to Remove and Insert Needles 15 *Needle position 15 *To remove needle(s 15 *To insert - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 6

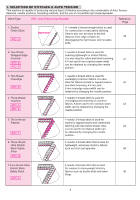

capable of producing various types of stitches according to the combination of Auto Tension Selected, needle positions, threading mm overlock seam width can be obtained by changing the needle position. 1-needle 2-thread stitch is used for overedging common fabrics. It is also ideal for flatlock - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 7

Tension Dial Selected 8. Four-thread Safety Stitch ATD: I The 4-thread stitch is a safety stitch made up of combined 2-thread overedge and double chainstitch. Reference Page 47 9. Five-thread Safety Stitch Wide ATD: B 10. Five-thread Safety Stitch Narrow ATD: A 11. Cover Stitch Narrow (2.8mm - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 8

* Depending on the needle positions used, this machine can sew 2-thread and 3-thread standard width 4 mm overedge and a 6 mm wide overedge seams. knob. (See page 31) Overedge width Needle used Needle thread tension fine tuning 4.0 mm Overedge right needle Blue 6.0 mm Overedge left needle Orange 7 - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 9

7 Ultra - Stretch mock A N N L 46 Safety Stitch 8 Four - Thread I NNL 47 Safety Stitch Five - Thread 9 Safety Stitch BNNL 48 Wide Five - Thread 10 Safety Stitch ANNL 48 Narrow Cover stitch 2.8mm 11 Narrow KNNC 51 12 Cover stitch Wide 5.6mm HNNC 51 5.6mm 13 Triple Cover - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 10

size) 2. Knife (stationary) 3. Thread Unwinder spool cap 4. Anti-spill net 5. Oiler 6. Allen Screw driver (small) 7. Tweezers 8. Needle set 9. Brush 10. Cone Adapters 11. Waste tray 12. Machine cover size or type in this overlock. Singer needle #2022 size 14/90 is furnished with the machine. Only use Needle - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 11

1. Thread guides and holder 2. Handle 3. Left needle thread tension fine tuning lever (orange) 4. Right needle thread tension fine tuning lever (blue) 5. Upper looper thread tension fine tuning lever (green) 6. Lower looper thread tension fine tuning lever (red) 7. Chain stitch looper thread tension - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 12

PRINCIPAL PARTS 19. Presser bar lifter and tension release 20. Differential feed adjusting dial 21. Cutting width dial 22. Presser foot pressure adjusting dial 22 19 20 21 11 - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 13

6. HOW TO OPEN LOOPER COVER Caution: Be sure to turn off power switch. Push the cover to the right as far as it will go. Pull cover down toward you. Caution: Be sure looper cover is closed when sewing. Note: Machine will not operate when Looper Cover is open. 1 2 7. PRINCIPAL PARTS BEHIND THE - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 14

POLARIZED PLUG INFORMATION (FOR U.S.A. & CANADA ONLY) This appliance has a polarized plug (one blade wider than the other). To reduce the risk of electric shock, this plug is intended to fit in a polarized outlet only way. If the plug does not fit fully in the outlet, reverse the plug. If it still - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 15

when they are correctly positioned. Center the thread guides above the spool pins. Place thread over the cone adapters on the spool pins. Note: Your new machine is threaded to sew Triple Cover Stitch. Refer to Page 30 for instructions on tying on to the threads. Anti-spill Net When using synthetic - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 16

11. HOW TO REMOVE AND INSERT NEEDLES Needle Position With this machine, five needles can be inserted into the needle clamp as shown in the drawing but only one or two or three needles are to be used for sewing. Do not attempt to use four or five needles. The Instruction machine uses Singer #2022 - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 17

Stitch 1. Upper looper thread Green 2. Lower looper thread Red 3. Chain stitch looper thread Brown 4. Right needle thread Blue 5. Chain stitch needle thread Orange Chain stitch Overlock 54 1 23 C L 2 1 Threading Diagram: Cover Stitch A color coded threading diagram is located inside - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 18

The Machine Correctly Caution: Be sure to turn off power switch. Note: The instructions on this page and the following pages will guide you through the proper threading for each color coded threading path. Before threading, refer to the Handy Reference Chart for information on Stitch Types, Settings - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 19

lifter to release Tension discs. 8 4 9 9 5 8 7 6 1 2 3 4 10 5 9 8 7 6 Pass thread from back to the front through the thread guide 1. 1 Thread the top cover thread guide by pulling 2 the thread towards the left until it slips under guide. Then pull thread along the right side of - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 20

the point of the tweezers slightly from left and to the right of threading guide 4. Place the thread with the point of the tweezers slightly from front and to the back of threading guide 5. 10 9 8 7 4 5 6 4 8 5 7 6 Thread the looper eye (A) from front to back. Pull about 10cm (4 inches) of - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 21

presser bar lifter to release Tension discs. 10 11 9 Pass thread from back to the front through the thread guide 1. 1 2 3 4 5 6 7 8 1 Thread the top cover thread guide by pulling the thread towards the left until it slips under guide. Then pull thread along the right side of 2 button as - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 22

area of the machine following the brown color-coded thread guides 4~11. Note: Use the tweezers provided in the accessory case to aid in threading the looper. Place the thread with the point of the tweezers through threading guide 4. Place the thread with the point of the tweezers through the front - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 23

into the rear slot on the thread guide 5 and the slot of take-up lever cover 6. Then slip thread into the right slot on the thread guide 7, and into the right slot on the thread guide 8. Before threading eye of needle, slip thread behind thread guide located on the bottom of the needle clamp. 22 - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 24

bar lifter to release Tension discs. Pass thread from back to the front through the thread guide 1. 9 1 2 3 6 7 8 54 9 1 Thread the top cover Thread guide by pulling 2 the thread towards the left until it slips under 2 guide. Then pull thread along the right side of button as - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 25

the slot of take-up lever cover 6. Then continue by slipping thread into the middle slot of the thread guides 7 and 8. Note: For 4 thread overlock left needle: Use needle A. Before threading eye of needle, slip thread behind thread guide located on the bottom of the needle clamp. Note: For chain - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 26

bar lifter to release Tension discs. Pass thread from back to the front through the thread guide 1. 1 2 3 6 7 8 54 9 1 Thread the top cover thread guide by pulling the thread towards the left until it slips under 2 guide. Then pull thread along the right side of button as illustrated - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 27

5 and slot of take-up lever cover 6. Then slip thread into left slots of thread guides 7 and 8. Before threading eye of needle, make sure thread is in front of thread guide located on the bottom of the needle clamp. 7 6 8 4 5 9 Thread the eye of the left needle 9. Note: Use of tweezers in - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 28

from back to the front through the thread guide 1. 1 Thread the top cover thread guide by pulling the thread towards the left until it slips under guide. 2 Then pull thread along the right side of button as illustrated. While holding thread with fingers, pass it between the tension discs - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 29

bar lifter to release Tension discs. Pass thread from back to the front through the thread guide 1. 9 1 6 7 8 5 2 3 4 9 1 Thread the top cover thread guide by pulling 2 the thread towards the left until it slips under guide. Then pull thread along the right side of 2 button as - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 30

the slot of the Take-up Lever Cover 6. Slip the thread into the right slots for thread guides 7 and 8. Before threading eye of needle, make sure thread is in front of thread guide located on the bottom of the needle clamp for Cover stitch. Thread the eye of the right needle 9. Note: Use of tweezers - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 31

Presser foot by lowering presser bar lifter to release Tension discs. Pull the threads through the machine one at a time. If threads do not pull easily, check for tangles on thread guides or looping under thread stand. When pulling thread through the needles, STOP when the knot is in front of the - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 32

(15/64 inch) b) When only right needle is used 4 mm (10/64 inch) c) When using chain stitch needle 8.8 mm (11/32 inch) 6.0 mm (15/64") Left needle 4.0 mm (10/64") 8.8 mm (11/32") Right needle Chain stitch needle Width Adjustment with Adjustment Knob Use of width adjustment knob will permit - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 33

Width adjustment knob As shown on the illustration, turn the dial counter clockwise to increase width of cutting, and clockwise to decrease width of cutting. N 5.5 6.5 16. HOW TO ADJUST THE PRESSER FOOT PRESSURE The presser foot pressure of this machine is pre-adjusted at the factory to suit the - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 34

17. DIFFERENTIAL FEED Differential feed is a system which "stretches" or "gathers" the fabric, when the amount of feed of front 2.0 feed dogs in relation to the rear feed dogs is changed. 1.5 The differential feed ratio ranges from 1:0.6~1:2.0. Adjustment is made by means of the differential - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 35

Stretch Overedge Stretch overedge is ideal for sewing decorative collars, sleeves, skirt hems, etc. on loosely knit and woven fabrics. To set the differential feed adjusting dial for stretch Set differential feed adjusting lever knob above setting "N". 2.0 1.5 N 0.8 0.6 To sew a seam, apply - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 36

18. HOW TO DISENGAGE MOVABLE UPPER KNIFE Caution: Be sure to turn off power switch. To place movable knife in nonworking position Open looper cover (page 12). Pull the movable knife holder to the right as far as it will go. Turn the holder toward counter clockwise until the knife clicks into a lock - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 37

19. TO CONVERT UPPER LOOPER TO SPREADER Caution: Be sure to turn off power switch. When not threading the upper looper, the spreader must be engaged into the upper looper eye. To Use the Spreader To engage the spreader, raise the white handle - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 38

20. STANDARD OVEREDGE AND ROLLED HEM STITCHING To Sew Standard Overedge Set seam width finger knob to N to move seam width finger to standard overedge sewing position. Note: Be sure to push seam width finger knob as far as it will go in the direction of setting N. N R To Sew Rolled Hem Set seam - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 39

The following instructions do not apply to cover stitch. For instructions on cover stitch, see page 49 "How to Sew a Cover Stitch." When the machine is completely threaded, bring all of the threads across the presser foot fitted on this machine. Use this mark as a guide when sewing. 38 Mark Mark - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 40

tuned with the Fine Tuning Levers according to the following variables: 1) Type and thickness of fabric 2) Needle size 3) Size, type and fibre content of thread * Stitch length for double chain stitch should be set at over 2mm. Correct Balance Set auto tension dial to D as shown on illustration and - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 41

guide plate Caution: Be sure to turn off the power switch. a) Move knife into nonworking position See page 35 for instructions When starting to sew, pull the thread chain lightly to the rear of machine until the needle penetrates the fabric. When starting to sew after threading the machine, sew 2 ~ 3 - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 42

the Fine Tuning Levers according to the following variables: 1) Type and thickness of fabric 2) Needle size 3) Size, type and fibre content of thread NEEDLE POSITION SEAM WIDTH FINGER KNOB STITCH LENGTH SPREADER N 2~4 USE Correct Balance Set auto tension dial to D or G as shown on illustration - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 43

Fine Tuning Levers according to the following variables: 1) Type and thickness of fabric 2) Needle size 3) Size, type and fibre content of thread * See page 36 for instructions on converting upper looper to spreader. Correct Balance Set auto tension dial to E as shown on illustration and test sew on - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 44

with the Fine Tuning Levers according to the following variables: 1) Type and thickness of fabric 2) Needle size 3) Size, type and fibre content of thread Correct Balance Set auto tension dial to A or B as shown on illustration and test sew on a sample of your fabric. NEEDLE POSITION SEAM WIDTH - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 45

Set auto tension dial to F as shown on illustration and test sew on a sample of your fabric. Needle thread Upper looper thread Topside Needle thread Lower looper thread Underside Fabric Tension Dial Orange Blue Green Red Medium weight Brown Fabric Tension Dial Orange Blue Green Red Medium - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 46

with the Fine Tuning Levers according to the following variables: 1) Type and thickness of fabric 2) Needle size 3) Size, type and fibre content of thread Correct Balance Set auto tension dial to G as shown on illustration and test sew on a sample of your fabric. ATD:G NEEDLE POSITION SEAM WIDTH - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 47

Needle thread Left needle thread Topside Lower looper thread Underside Upper looper thread Right Needle thread Left needle thread Topside Lower looper thread Underside Upper looper thread Right Needle thread Left needle thread Topside Lower looper thread Underside Upper looper thread When - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 48

Brown Lower looper thread Overedge Needle thread Chain stitch Needle thread Topside Lower looper thread Chain stitch looper thread Underside Overedge Needle thread Chain stitch Needle thread Topside Lower looper thread Chain stitch looper thread Underside Overedge Needle thread Chain stitch - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 49

Orange Blue Green Red Medium weight Brown Upper looper thread Lower looper thread Overedge Needle thread Chain stitch looper thread Topside Chain stitch needle thread Upper looper thread Underside Lower looper thread When the lower looper thread appears on the top of the fabric; -Move the - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 50

and cover stitch left needle (C). (See pages 25 ~ 29) Pass thread through needles (E), (D) and (C) and thread cover stitch looper [brown] (See pages 20 ~ 21) Install seam guide plate. (See page 40) The graduations on seam guide plate indicate the distance from cover stitch middle needle. Use it as - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 51

Additional Information About Cover Stitch Start and end of sewing Note: Follow the instructions given below when sewing cover stitches because chaining-off at the end of sewing is not possible. At start of sewing Raise presser foot by - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 52

tuned with the Fine Tuning Levers according to the following variables: 1) Type and thickness of fabric 2) Needle size 3) Size, type and fibre content of thread * Stitch length for cover stitch should be set at over N (2.5 mm). Correct Balance Set auto tension dial to K or H as shown on illustration - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 53

tuned with the Fine Tuning Levers according to the following variables: 1) Type and thickness of fabric 2) Needle size 3) Size, type and fibre content of thread * Stitch length for cover stitch should be set at over N (2.5 mm). Correct Balance Set auto tension dial to J as shown on illustration and - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 54

fabric edge, knot the needle threads (2 or 3 threads) together first, as shown on the illustration. Then, tie these threads with the looper threads. When sewing is stopped halfway, pull out the needle threads (2 or 3 threads) on the underside of the fabric and knot the threads in the same manner as - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 55

face of seam width finger support plate with R mark on needle plate by turning seam width adjustment knob, as required. Set stitch length dial to "1~2" and a fine seam will be sewn. Needle: Singer Cat. No. 2022 #14/90 or 2022 #11/80 Thread: A variety of thread combinations can be used for rolled - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 56

Rolled Hem Stitching Correct Balance Set auto tension dial to A as shown on illustration and test sew on a sample of your fabric. 2) 3-thread Upper Looper Thread Wrapped Rolled Hem Stitching Correct Balance Set auto tension dial to C as shown on illustration and test sew on a sample of your fabric - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 57

Standard Rolled Hem Stitching Correct Balance Set auto tension dial to E as shown on illustration and test sew on a sample of your fabric. 4) 2-thread Lower Thread Wrapped Rolled Hem Stitching Correct Balance Set auto tension dial to D as shown on illustration and test sew on a sample of your fabric - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 58

Additional Information About Rolled Hemming Hold the thread chain when you begin sewing to keep it from curling inch) since the cutting width cannot be set below 3.5 mm (9/64 inch). To Secure the Rolled Hem Thread Chain Apply a small drop of liquid seam sealant to the end of the seam. Allow to dry, - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 59

25. STITCH VARIATIONS AND SEWING TECHNIQUES How to Sew a Flatlock Decorative Seam A flatlock stitch is achieved by adjusting the tension of the 2-thread or 3-thread overlock stitch, sewing the seam, and then pulling the fabric apart to flatten the seam. The flatlock stitch can be used as a - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 60

tensions must be correctly fine tuned for the fabric to pull flat. The upper looper thread is the prominent thread in the flatlock stitch. Place a decorative thread in the upper looper and inconspicuous threads in the lower looper and needle. For a ladder stitch, sew seam with right sides together - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 61

to Sew Pin Tucks Sew decorative pin tucks on the fabric before cutting out the garment. Use overedge right needle and adjust machine for a narrow 3-thread overlock stitch. (See page 43) Note: The rolled hemstitch can also be used for this technique. Place the movable upper knife in the nonworking - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 62

one stitch beyond point (A) and stop. Raise needle and presser foot. Pull the fabric to the rear of the machine just enough to release the thread caught on the finger of the needle plate. Note: Presser foot has been removed to show detail. Turn the fabric and lower the presser foot - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 63

away from the cutting action of the knives. Caution: Sewing over pins will damage and /or destroy the cutting edge of the knives. Securing the Thread Chain Thread a large eye, hand sewing needle (such as a tapestry needle) with the thread chain. Insert the needle into the end of the seam to secure - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 64

How to Reinforce a Seam Inserting twill tape while overedge sewing will stabilize the seam. Insert the tape through the hole in the front of the foot. Position the tape under the foot to the back of the machine and sew the garment seam. The tape is attached as the seam is sewn. Braiding by Chaining - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 65

26. MACHINE MAINTENANCE An overlock machine requires more maintenance than a conventional machine for two reasons: 1) A lot of lint is produced due to the cutting action of the knives. 2) An overlock runs at a very high speed and needs to be oiled frequently to lubricate the internal working parts. - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 66

dull. The moveable upper knife can be replaced according to the directions provided, however if there are any difficulties experienced, consult your Singer representative to make the replacement. Be sure that the power line plug is disconnected from the electric source. Open the looper cover and - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 67

How to Exchange Light Bulb Danger: Always unplug before re-lamping. Light bulb is available at your Singer shop. Take old bulb to the Singer shop and ask for the same bulb. If voltage indicated on the electrical rating plate of your machine is 120V, ask for light bulb conforming - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 68

27. OPTIONAL ACCESSORIES The following optional presser feet specially prepared for this machine are available at extra-charge. Note: Do not use presser foot made for other machines. Use of such presser foot may result in interference with the needle and knife and can be hazardous. A The snap-on - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 69

Optional Presser Feet 1) Elastic Foot This foot is used for attaching elastic tape to the garment and the amount of contraction of the elastic tape can be adjusted as required. 2) Blind Hem Foot This foot is for sewing cuffs on knit fabrics, skirt and trouser seams where seam should not be visible. - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 70

28. TROUBLESHOOTING CHART Problem Fabric does not feed well Solution - Lengthen stitch length. Point. - Use only high quality thread. - Loosen thread tension. Stitch skip - Insert new needles, current needles may be bent or have a blunt point. Use only Singer Branded Style 2022 Needles - Tighten - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 71

AND NEEDLE Type of Fabric WOVEN Lightweight Lawn, Organdy, Voile, Crepe, etc. Type of Thread Cotton: #100 Silk/ Rayon: #100 Spun: #80 ~ #90 Polyester: #80 ~ #100 Needle Singer Cat. #2022 #11/80 Medium Weight Muslin, Seersucker, Satin, Gabardine, Broadcloth, etc Cotton: #60 ~ #80 Silk/ Rayon - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 72

stitch needle gauge Needle bar stroke Pressure foot rise Needle Number of threads Machine dimensions (mm) Width Depth Height Weight (kg) Specification 1, 4 mm) Two needles: 2.8 mm (narrow), 5.6 mm (wide) Triple needles: 5.6 mm 27 mm 4.5 mm Singer #2022 (EL x 705) #14, #11 2~5 360 290 300 9.0 kgs 71 - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 73

Please note that on disposal, this product must be safely recycled in accordance with relevant National legislation relating to electrical /electronic products. If in doubt please contact your retailer for guidance. - Singer 14T968DC PROFESIONAL 5 | Instruction Manual 31 - Page 74

G5P21

14T968DC

Instruction Book