Whirlpool KDSS907SSS Installation Instructions - Page 16

Bwarning

|

View all Whirlpool KDSS907SSS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

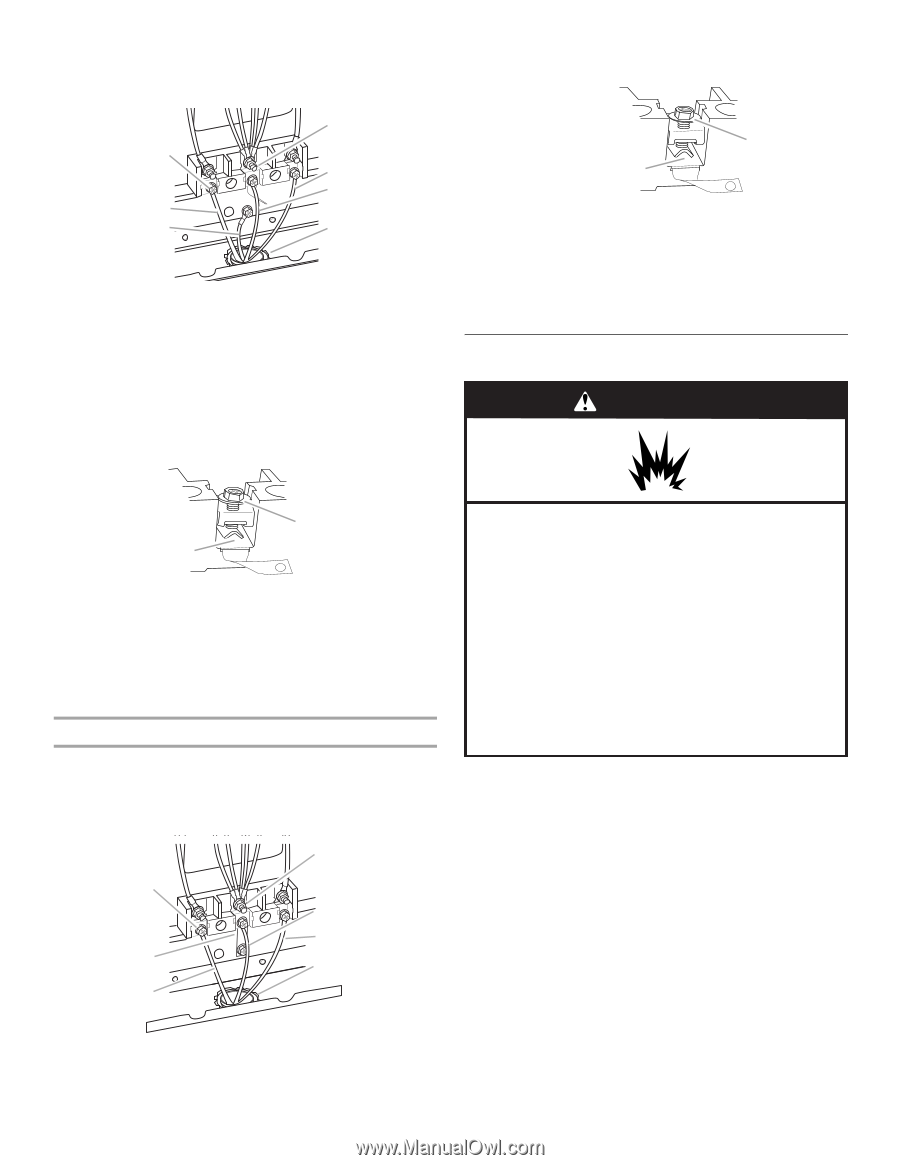

2. Connect the bare ground wire to the range using the groundlink screw and cup washer. The ground wire must be attached first and must not contact any other terminal. 2. Insert the other 2 wires (lines 1 and 2) under the other 2 screw clamps. D C E F B A G A. Bare wire from power supply cable B. Line 1 C. Hex washer head screw D. Silver-colored terminal block screw E. Line 2 F. Neutral (white) wire G. UL listed conduit connector and power supply cable 3. Loosen (do not remove) the hex washer head screw and insert the neutral (white) wire under the screw clamp at the bottom of the center position terminal connector. 4. Insert the other 2 wires (lines 1 and 2) under the other 2 screw clamps. B A A. Insert wire under screw clamp. B. Hex washer head screw 3. Securely tighten the hex washer head screws to 35 lbs-in. (4.0 N-m) minimum torque to make a proper electrical connection. 4. Tighten the locking ring of the conduit connector. 5. Replace the terminal block cover with screw. Make Gas Connection WARNING B A A. Insert wire under screw clamp. B. Hex washer head screw 5. Securely tighten the hex washer head screws to 35 lbs-in. (4.0 N-m) minimum torque to make proper electrical connection. 6. Tighten the locking ring of the conduit connector. 7. Replace the terminal block cover with screw. 3-wire connection: Direct Wire Use this method only if local codes permit connecting ground conductor to neutral supply wire. 1. Loosen (do not remove) the hex washer head screws and insert the neutral (white) wire under the screw clamp at the bottom of the center position terminal connector. D C E F B G A Explosion Hazard Use a new CSA International approved gas supply line. Install a shut-off valve. Securely tighten all gas connections. If connected to LP, have a qualified person make sure gas pressure does not exceed 14" (36 cm) water column. Examples of a qualified person include: licensed heating personnel, authorized gas company personnel, and authorized service personnel. Failure to do so can result in death, explosion, or fire. Typical rigid pipe connection A combination of pipe fittings must be used to connect the range to the existing gas line. Your connections may be different, according to the supply line type, size and location. 1. Apply pipe-joint compound made for use with LP gas to all pipe thread connections. A. Line 1 B. Ground-link C. Hex washer head screw D. Silver-colored terminal block screw E. Neutral (white) wire F. Line 2 G. UL listed conduit connector and power supply cable 16